Falk

®

CT-Series Gear Drives • Operation and Maintenance

(Page 6 of 7)

Sizes 2160 thru 2400

GR3-014

Rexnord

January 2017

3001 W. Canal St., Milwaukee, WI 53208-4200 USA

NEW

Telephone: 414-937-4359 Fax: 414-937-4359 www.rexnord.com

8. MAINTENANCE

8.1 OIL CHANGE

The first oil change after about 200 working hours.

Subsequent oil changes must be made after every

1500 to 5000 operating hours, depending on working

conditions. The oil change intervals should, however,

not exceed 18 months.

If possible, the oil should be drained warm.

Where the gear unit has to be stored for a long time,

consult us in advance for advice and to enable us to

give a special treatment before dispatch, for storing

the gear unit for a longer time. As an alternative to the

oil- change intervals indicated in Table 1 (see item 8.5)

it is possible to have the oil sample tested at regular

intervals by the Technical Service of the relevant oil

company and to have it released for further use.

If re-usability has been confirmed, no oil change will

be necessary.

Drain the oil while the gear unit is still warm, i.e.

immediately after shutting down the machinery. When

changing the oil, always re-fill the gear unit with the

same type of oil. Never mix different types of oil and/

or oils made by different manufacturers. Polyglycol-

based synthetic oils in particular must not be mixed

with PAO-based synthetic oils or mineral oils. If

changing to a different grade or make of oil, the gear

unit must, if necessary, be flushed out with the new oil

grade. Flushing is not necessary, if the new service

oil is fully compatible with the old service oil in all

respects. Compatibility must be confirmed by the oil

supplier. If there is a change to another oil grade or

make, Rexnord recommends flushing out the gear unit

with the new grade of service oil.

When changing the oil, the housing and the oil-

supply system, if available, must be flushed with oil to

remove sludge, metal particles and oil residue. Use

the same type of oil as is used for normal operation.

High-viscosity oils must be heated beforehand using

suitable means. Ensure that all residues have been

removed before filling with fresh oil.

For oil renewal period refer to Table 1 based on the

operating temperature.

Place a suitable container under the oil-draining point

of the gear-unit housing.

Unscrew the breather plug including reducing screw

at the housing top.

Unscrew the screw plug or the open oil-drain cock and

drain the oil into the collecting container.

Drain the oil from the oil-supply system (see operating

instructions to the oil-supply system).

There is a danger of scalding from the hot oil

emerging from the housing. Wear safety gloves and

safety glasses! Remove any oil spillage immediately

with an oil-binding agent.

Check the condition of the sealing ring (the sealing

ring is vulcanized onto the oil-drain plug). If necessary,

use a new oil-drain plug.

Screw in the screw plug again and shut the oil-drain cock.

Clean the oil filter in the oil-cooling system (see

operating instructions of the oil-supply system).

Clean the breather plug (see item 8.2).

Screw in the breather plug including reducing screw.

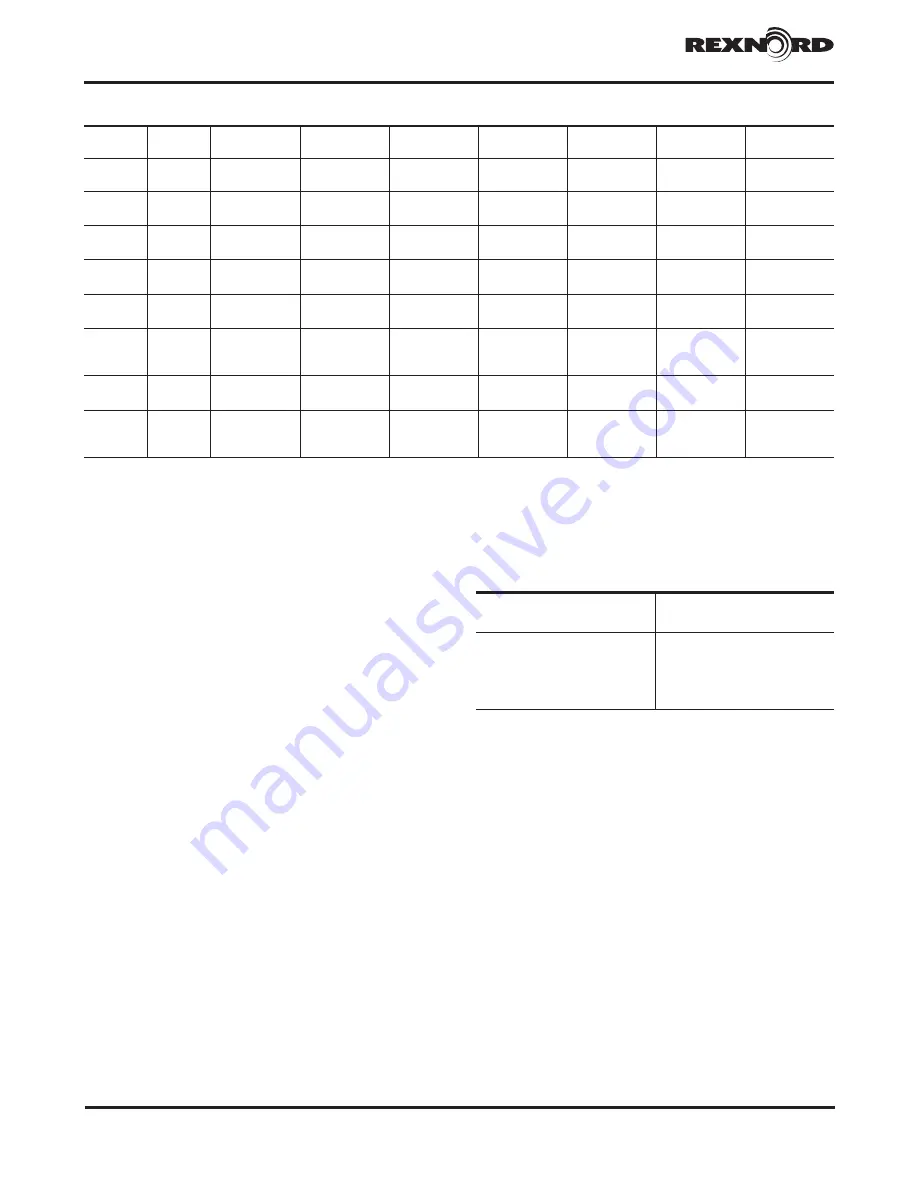

Table 1 — Oil Renewal Period

Unit operating temperature (ºC)

Renewal period

Mineral oil ISO VG Class

Up to 75ºC

4320 hrs or 6 months

75ºC to 85ºC

3000 hrs or 6 months

85ºC to 95ºC

2500 hrs or 3 months

95ºC to 105ºC

2000 hrs or 3 months

Lubricants Chart

DIN (ISO)

ISO VG

Class

Mobil

Shell

Total

Castrol

MAK Lubricants

Servo

HP

CLP

VG 150

...

...

...

Castrol

Alpha SP 150

Bharath Amocam

Oil 150

Servo Mesh SP

150

Parthan EP 150

CLP-HP

VG 150

Mobilgear SHC

XMP150

...

Carter SH

150

Optigear Synthetic

X 150

...

Servosyngear 150

...

CLP

VG 220

Mobilgear

XMP220

Shell Omala

F220

Carter EP

220

Castrol

Alpha SP 150

Bharath Amocam

Oil 220

Servo Mesh SP

220

Parthan EP 220

CLP-HP

VG 220

Mobilgear SHC

XMP220

Shell Omala

Oil HD 220

Carter SH

220

Optigear Synthetic

A 150

...

Servosvneear 220

...

CLP

VG 320

Mobilgear

XMP320

Shell Omala

F320

Carter EP

320

Castrol

Alpha SP 320

Bharath Amocam

Oil 220

Servo Mesh SP

320

Parthan EP 320

CLP-HP

VG 320

Mobilgear SHC

XMP320

Mobil SHC 632

Shell Omala

Oil HD 320

Carter SH

320

Optigear Synthetic

A 320

...

Servosyngear 320

...

CLP

VG 460

Mobilgear

XMP460

Shell Omala

F460

Carter EP

460

Castrol

Alpha SP 460

Bharath Amocam

Oil 460

Servo Mesh SP

460

Parthan EP 460

CLP-HP

VG 460

Mobilgear SHC

XMP460

Mobil SHC 634

Shell Omala

Oil HD 460

Carter SH

460

Optigear Synthetic

A 460

...

Servosyngear 460

...