Falk

®

CT-Series Gear Drives • Operation and Maintenance

Sizes 2160 thru 2400

(Page 7 of 7)

Rexnord

GR3-014

3001 W. Canal St., Milwaukee, WI 53208-4200

January 2017

Telephone: 414-937-4359 Fax: 414-937-4359 www.rexnord.com

NEW

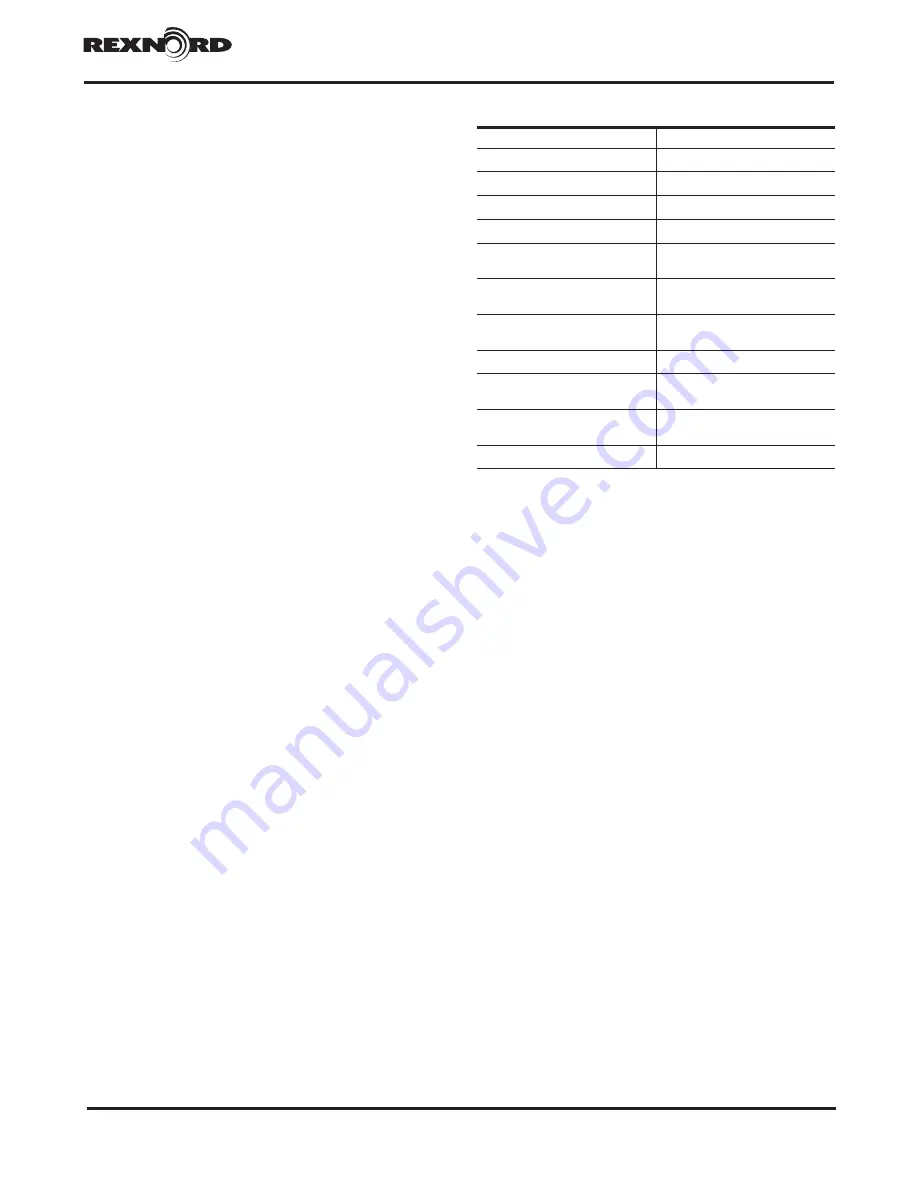

Table 2 — Maintenance

Measure

Period

Check the oil temperature

Daily

Check for unusual gear-unit noise

Daily

Check the oil level

Monthly

Check the gear unit for leaks

Monthly

Test the water content of the oil

After approx. 500 operating hours,

at least once per year

Perform the first oil change

Approx. 200 operating hours after

start-up

Perform oil changes

After every 1500 to 5000 operating

hours

Clean air filter

Every 3 months

Clean the gear unit

Depending on requirements, at

least every 2 years

Check tightness of screw

connections

After first oil change, then every

2 years

Inspection of the gear unit

Approx. every 2 years

8.2 CLEAN THE BREATHER PLUG

If a layer of dust has built up, the breather plug must

be cleaned, whether or not the minimum period of 3

months has expired.

Unscrew the breather plug including the reducing

screw.

Clean the breather plug using benzene or a similar

cleanser.

Dry the breather plug.

8.3 TOP UP OIL

The instructions in item 7.1 must be observed!

Always top up with the same type of oil as already

used in the unit (see also item 8.1).

8.4 CHECK TIGHTNESS OF SCREW CORRECTIONS

The instructions in item 8.1 must be observed.

Close the stop valves in the coolant in- and outflow

pipes (for gear units with water oil-cooling system).

Check tightness of all screw connections.

8.5 GENERAL NOTES ON MAINTENANCE

All maintenance and repair work must be done with

care and by duly trained and qualified personnel only.

Switch the gear unit and add-on components off.

Secure the drive unit to prevent it from being started up

unintentionally. Attach a warning notice to the start switch!

The periods indicated in Table 2 depend on the

conditions under which the gear unit is operated.

Only average periods can therefore be stated here.

These refer to:

• A daily operating time of 24 h

• An input-drive speed of 1500 1/min

• Maximum oil temperature of 90°C (applies to

mineral oil)

• 100°C (applies to synthetic oil)

The operator must ensure that the intervals stated in

Table 2 are adhered to.

Under different operating conditions the periods

indicated above must be adjusted accordingly.

8.6 GENERAL OIL-SERVICE LIVES

According to the oil manufacturers, the following are

the expected periods during which the oils can be

used without undergoing any significant change in

quality. They are calculated on the basis of an average

oil temperature of 80°C:

• For mineral oils, biologically degradable oils

and physiologically safe (synthetic esters) oils 2

years or 10,000 operating hours (does not apply

to natural esters, such as rapeseed oils).

• For poly-

α

-olefins and polyglycols, 4 years or

20,000 operating hours.

The actual service lives may differ. The general rule

is that an increase in temperature of 10°C will halve

the service life and temperature decrease of 10°C will

approximately double the service life.

8.7 DESCRIPTION OF MAINTENANCE

8.7.1

TEST WATER CONTENT OF OIL —

More

information about examining the oil for water

content or conducting oil analyses is obtainable

from your lubricant manufacturer or our customer

service. For reference purposes, a fresh sample

of the operating lubricating oil used must be

sent with the used oil sample to the analyzing

institute for analysis. The oil sample must be

taken downstream of the filter of the oil-supply

system while the gear unit is running. A suitable

connection point is normally located upstream

of the gear unit input (e.g. oil-drain cock in the

pressure line). A special sample container should

be filled with the specified quantity of oil. If there

is no such sample container available, at least

one litre of oil must be put in a clean, transport

worthy, sealable vessel.

8.7.2

OIL SUPPLY SYSTEM —

Be sure to observe the

operating instructions of the oil-supply system for

operation and maintenance.