TA Removal Tool

Removal of Quadrive

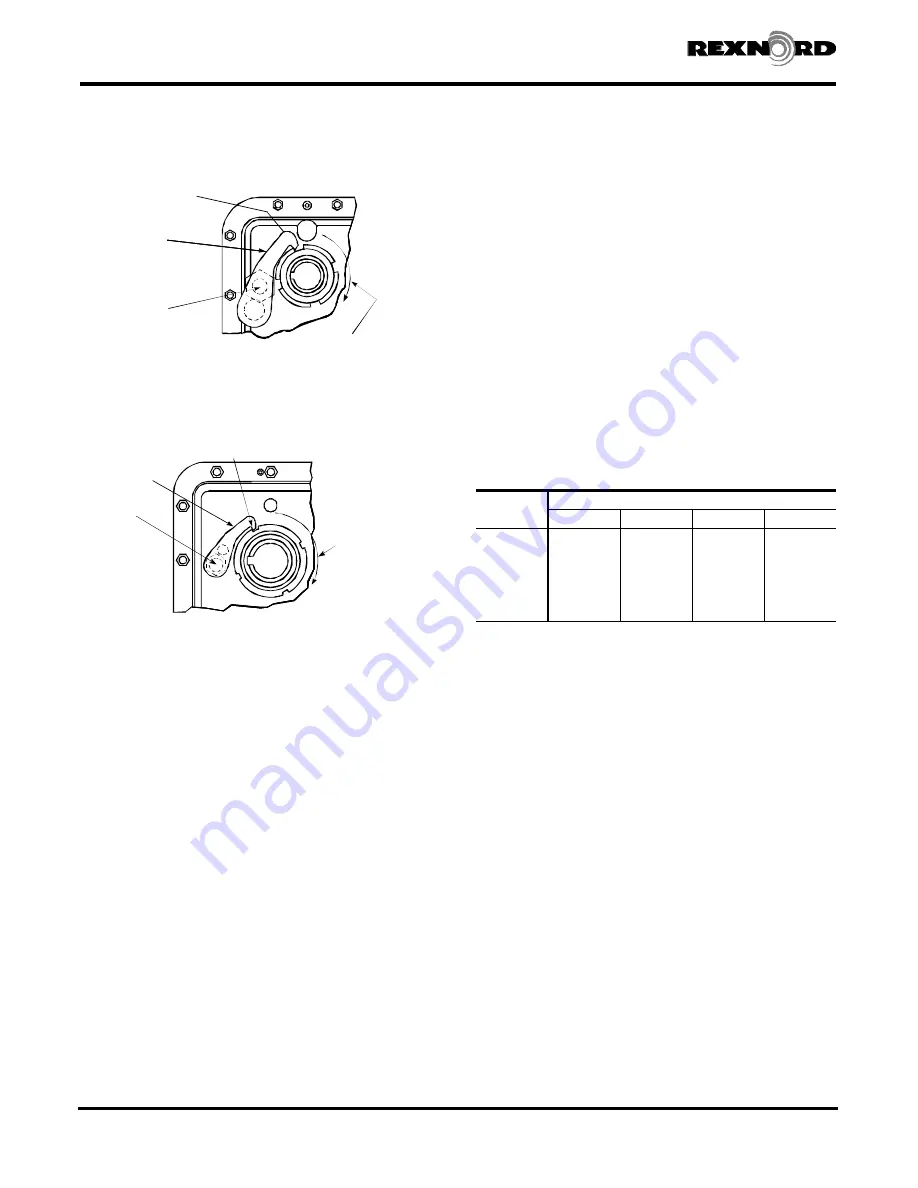

5. Use a spanner wrench to apply torque through the input

shaft keyway (Type J05 clockwise; Types J09, J14 or J25

counter-clockwise) to loosen the bushing nut.

CAUTION:

Never use the prime mover to produce the

torque needed. This could result in severe personal injury

or damage to the equipment.

To avoid damage to the drive or the removal tool, DO NOT

exceed the H.S. shaft torque values listed in Table 3. NOTE:

The nut will rotate freely for approximately 180° as it moves

from the locked to the removal position. Resistance will

indicate that unseating is occurring. Turn until the nut and

bushing are completely free. Now, prepare the drive for

lifting by disconnecting the torque arm at the drive end.

6.

ALTERNATE METHOD —

Torque may be applied to the

sheave or sprocket mounted on the input shaft.

Rexnord Industries, LLC 3001 W. Canal St., Milwaukee, WI 53208-4200 USA

378-200

(PN-2128394)

Telephone: 414-342-3131 Fax: 414-937-4359

November 2010

e-mail: [email protected] web: www.rexnord.com

Supersedes 6-07

TABLE 3 — Maximum Torque – H.S. Shaft

lb-ft (Nm)

DRIVE

SIZE

Drive Reduction

J05

J09

J14

J25

5107

164 (223)

88 (120)

58 (78)

33 (44)

5115

248 (336)

133 (181)

90 (121)

50 (68)

5203

406 (550)

224 (304)

143 (193)

79 (107)

5207

493 (668)

263 (357)

173 (234)

100 (136)

5215

677 (917)

371(503)

245 (332)

133 (181)

5307

762 (1 033)

405 (549)

278 (377)

150 (203)

5315

813 (1 102)

432 (585)

283 (384)

160 (217)

SIZES 5107, 5115, 5203, & 5207

ENGAGE TOOL

IN SLOT

TOOL

USE INNER

HOLE

LOW SPEED SHAFT

ROTATION

Figure 3

USE OUTER

HOLE

TOOL

ENGAGE TOOL IN SLOT

SIZES 5215, 5307, & 5315

LOW SPEED SHAFT

ROTATION

Figure 4

Appendix C

•

Falk™ Quadrive Shaft Mounted Drives Model A

(Page 30 of 44)

Sizes 5107-5315