TA Removal Tool

Introduction

The patented TA removal tool offers a positive method for

removing a TA Taper equipped Quadrive from the driven shaft.

This method uses the torque multiplying characteristic of the

drive to separate the drive from the bushing and driven shaft.

The removal tool is available in kit form suitable for use with

Sizes 5107 thru 5315. The kit can be ordered from your

Rexnord-Falk Distributor by specifying “TA Removal Kit - Part

0769406". NOTE: Use of this tool requires a minimum axial

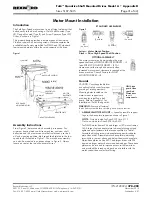

clearance ”M" shown in Figure 1 and Table 1.

CAUTION:

DO NOT modify the tool in any way OR use it in

another manner except to loosen the bushing nut as instructed

herein.

Preparation For Removal

WARNING:

Always “lock out” prime mover before working on

the Quadrive.

1. Quadrive shafts, input and output, must be free to rotate.

a) Remove any external load on the driven shaft.

b) Remove belts from input shaft sheave.

c) Remove the backstop (if so equipped). Refer to Section

II

— Step 10, for backstop removal instructions.

CAUTION:

DO NOT disconnect the drive from its torque

arm until the removal process is completed. In addition,

the drive must be supported during removal process. Use

a sling around the motor mount or as recommended in

SECTION

I

, Step 7. Be sure to take up the slack in the

sling before proceeding.

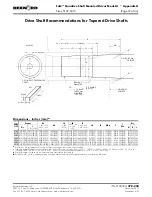

2. Loosen the setscrew on the O.D. of the bushing nut and

select the most convenient of the tapped holes in the

housing face for the threaded adapter. Figure 2.

3. Select the proper adapter from the tool kit. (Adapters are

marked with the Quadrive Size and part number.) Make sure

the tapped hole in the housing face is clean before inserting

the adapter. Apply tightening torque from Table 2.

4. Mount the removal tool as illustrated in Figure 3 or 4. It is

generally preferable to install the tool in a position where

its weight will tend to keep it engaged into the nut. Then

rotate the input shaft until the tool hook engages one of

the slots in the nut.

Rexnord Industries, LLC

(PN-2128394)

378-200

3001 W. Canal St.,Milwaukee, WI 53208-4200 USA Telephone: 414-342-3131

November 2010

Fax: 414-937-4359 e-mail: [email protected] web: www.rexnord.com

Supersedes 6-07

M

Figure 1

TABLE 1 — Minimum Tool Clearance –

Inches (mm)

DRIVE SIZE

M Dimension

5107

2.62 (67)

5115

2.62 (67)

5203

2.62 (67)

5207

2.62 (67)

5215

3.18 (81)

5307

3.18 (81)

5315

3.18 (81)

THREADED

ADAPTER

REMOVAL

TOOL

(3) TOOL

ADAPTER HOLES

DO NOT USE THIS HOLE

FOR SIZES 5107 & 5115

SETSCREW

Figure 2

TABLE 2 — Adapter Tightening Torque

DRIVE SIZE

Adapter

Part Number

Torque lb-ft (Nm)

5107

2111955

35 (47)

5115

2111956

70 (95)

5203

9111957

108 (146)

5207

2111958

120 (163)

5215

2111959

180 (244)

5307

2111959

180 (244)

5315

2111959

180 (244)

Falk™ Quadrive Shaft Mounted Drives Model A

•

Appendix C

Sizes 5107-5315

(Page 29 of 44)