The ZM 300 Ultra Centrifugal Mill

24

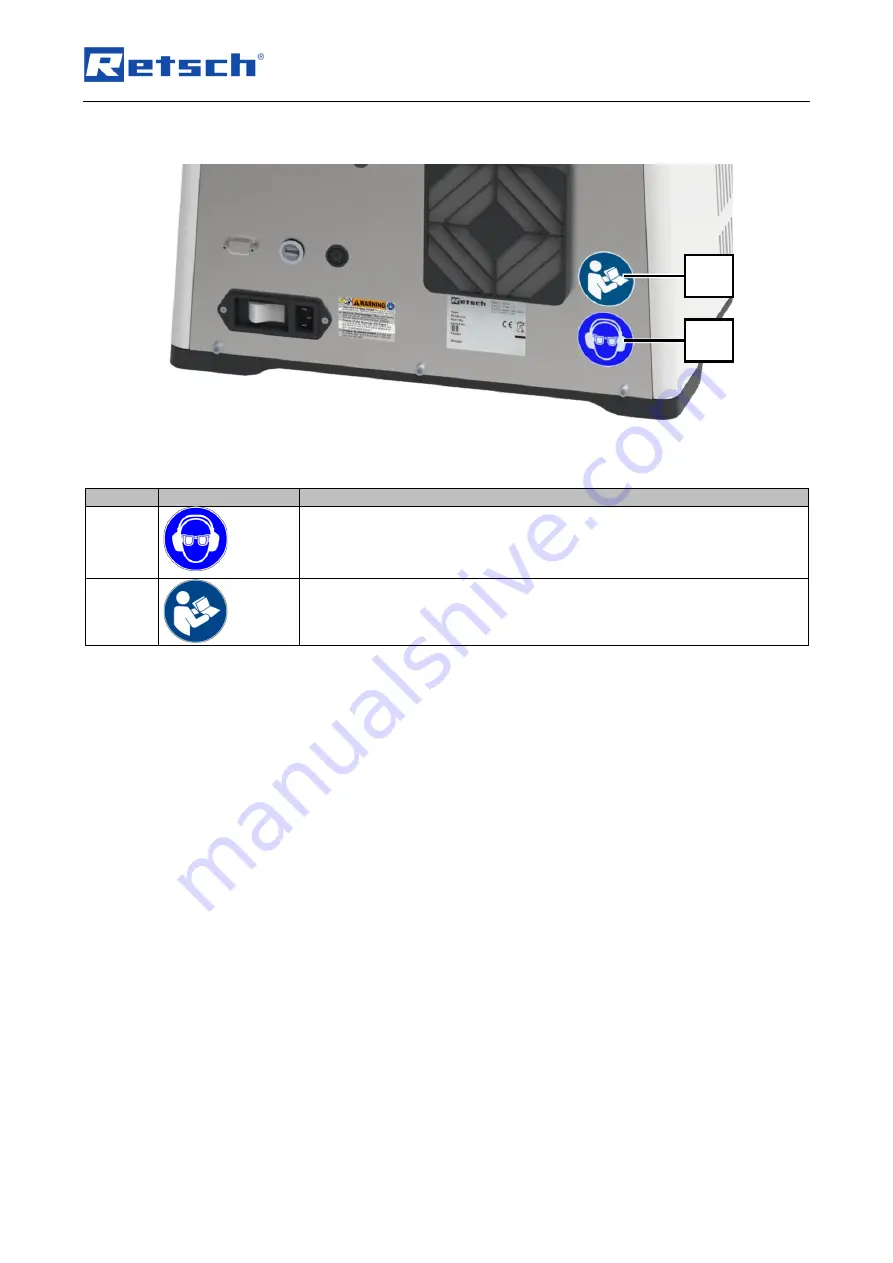

3.3 Instructions on the device

Fig. 6:

Notice on the device

Position

Element

Meaning

A

Eye and hearing protection must be worn when operating the device without noise

protection funnel. This PPE prevents eye injuries if sample material is ejected

during grinding and exposure to noise that can be caused by the grinding noise of

the device.

B

This instruction sign is located on the rear of the device near the main switch and

indicates the need to read the operating instructions before using the device.

B

A