20

Electrical connection of the cable remote control

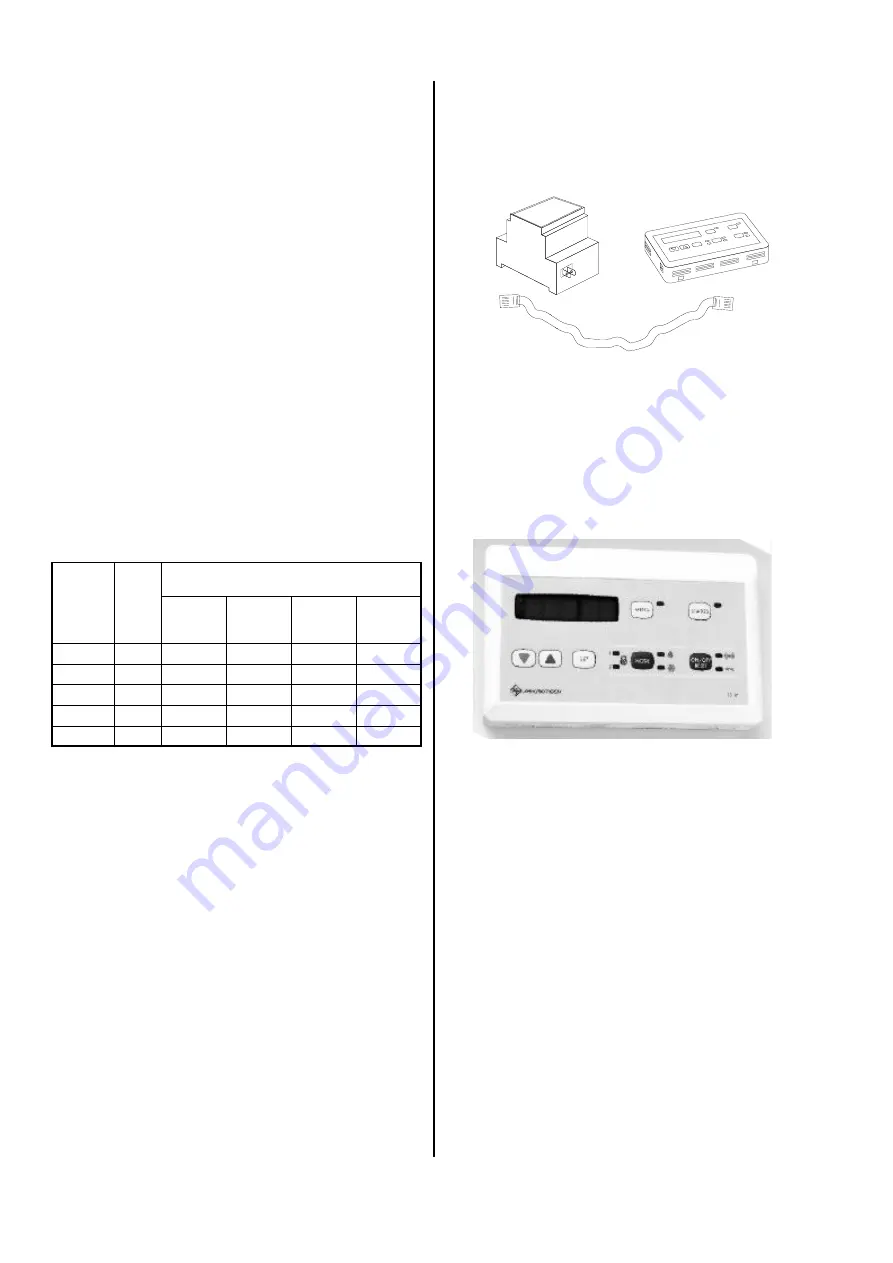

The remote control comes with an operating module

TS-W, the additional regulation module CS-DIN/TTL

and an interface line.

Cable Remote Control

The cable remote control can be purchased as an ac-

cessory. It is used to query and program the chiller from

a remote location.

In the factory, all models are programmed using the re-

mote control.

Install the remote control as follows:

1) Place the two, two wire connection lines between the

location where the remote control is to be assembled

and the switch box of the chiller. The minimum

cross-section is Cu 1.5 mm². The max. current may

not fall below 2 %.

2) Remove the assembly back panel of the operating

module and attach it to the setup location.

3) Clamp the lines to the terminal strips of the elec-

tronic board and make sure that the polarity is cor-

rect. Lock the operating module into place in the as-

sembly back panel.

4) Insert the additional module into the switch box of

the chiller.

5) Clamp the lines to the terminal strips of the previ-

ously mounted additional regulation module in the

switch box of the chiller.

6) Using the interface line, you can connect the addi-

tional regulation module and the CH–DIN regulation.

7) Test the function of the remote control.

Percent-

age of

ethylene

glycol

Correction factors when using a brine

made of ethylene glycol * and water

Cooling

capacity

Power

consump-

tion

Flow rate

Pressure

loss

Vol. %

°C

K

L

K

PE

K

V

K

D

0

0

1

1

1

1

20

-11

0.96

0.995

1.04

1.19

34

-20

0.95

0.990

1.09

1.35

40

-25

0.925

0.985

1.105

1.51

Anti-

freeze

* We recommend an ethylene glycol with inhibitors as

corrosion protection, e.g. antifreeze N or L.

Where the heat medium comes into contact with

drinking water or food, antifreeze L is to be given

preference because it contains the physiologically

harmless substance 1.2 propylene glycol.

The data provided in the table refers to antifreeze N.

Antifreeze L has other correction factors and thus a

different pressure loss!

Antifreeze to prevent freezing

During cold seasons of the year, it is possible that the

water in the chiller will freeze at temperatures below 0°C

which can cause damage, for example, to the plate heat

exchanger. The same applies to installed connection

lines and system parts in rooms not susceptible to frost.

For this reason, we recommend mixing the water with

an adequate amount of antifreeze (e.g. antifreeze N).

If brine (a mixture of water and frost protection) is not

used in the hydraulic cycle, the water is to be drained

from the system parts in areas susceptible to frost dur-

ing non-operation in the winter.

Appropriate shut-off and drainage mechanisms are to

be used. The amount of water drained out must be re-

filled before the next cooling season begins.

If the chiller is to be used throughout the whole year, e.

g. to air-condition a computer room) the hydraulic cycle

must be operated with brine.

When using brine, you must make sure that the pres-

sure loss increases as a result of the changing density

in the hydraulic cycle. Whether or not to use brine must

be considered when the hydraulic cycle is being set up.

The variable technical data can be found in the table be-

low:

The operating module is to be mounted in the desired

location. The operating module is connected to the

RKW with two, two-wire lines with a maximum length of

50 m. One line is used to transfer data and the other to

supply the current 12 V~ of the operating module. It is

not necessary to use an additional transformer.

The programmed data is transferred to the CH– DIN

regulation by an interface line.

CS-DIN/TTL

TS-W