d.

e.

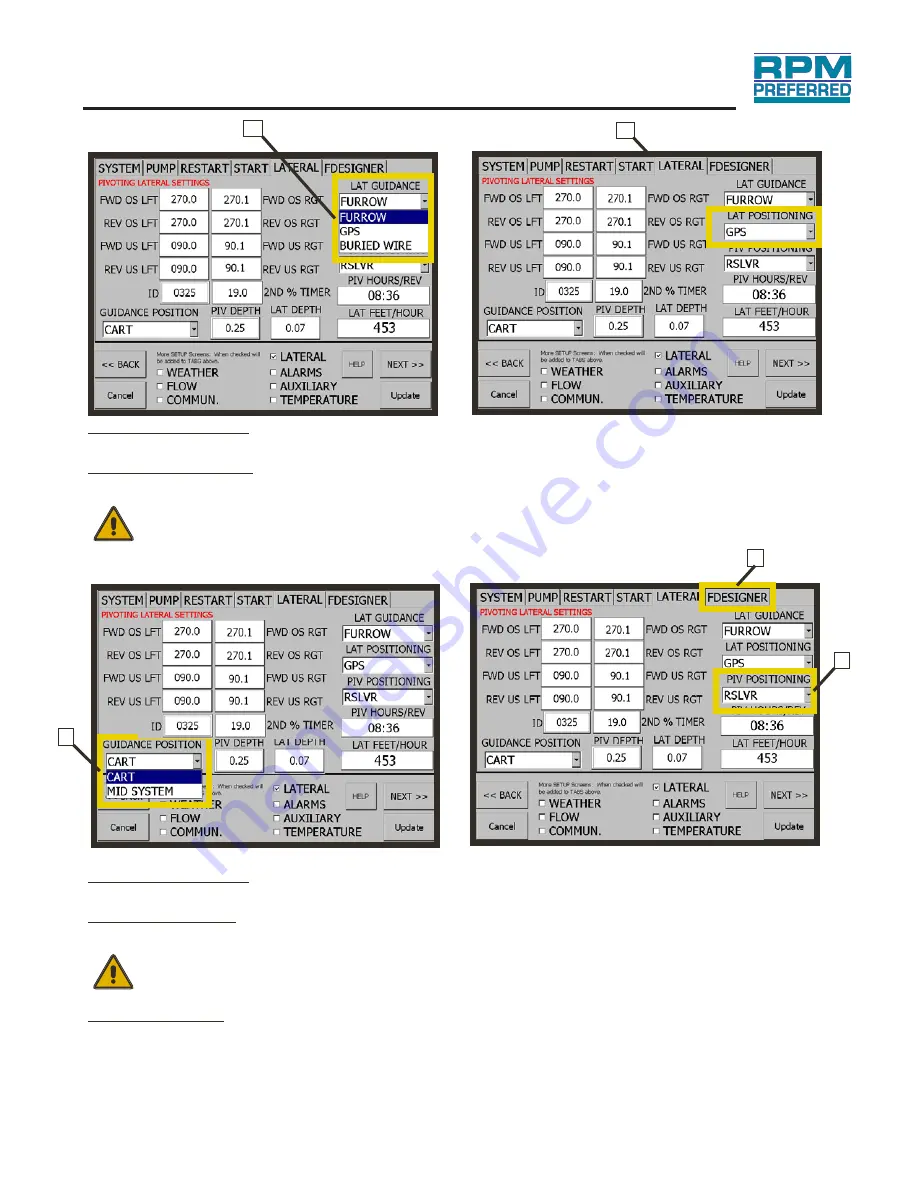

d. Lateral Guidance:

Highlight to select guidance to be used in field; Furrow, GPS, or Buried Wire.

e. Lateral Positioning

GPS is the default selection and is recommended.

DED REK should only be used if GPS is not functioning.

f. Guidance Position:

Select CART or MID SYSTEM depending upon where guidance is placed on the system.

g. Pivot Positioning

RSLVR is the default selection and is recommended.

DED REK should only be used if Resolver is not functioning

h. Field Designer:

Select tab now to start Field Designer. All other programming and setup will be completed

under this tab for pivoting lateral machines.

f.

g.

h.

Pivot/Lateral Setup

WITH TOUCH TECHNOLOGY

WITH TOUCH TECHNOLOGY

Touch

Screen

User

'

s

Manual

41