P36E-4 Zero Clearance Direct Vent Gas Fireplace

34

GAS LINE

INSTALLATION

The gas line is brought through the right of the

appliance. The gas valve is situated on the right

hand side of the unit and the gas inlet is on the

right hand side of the valve.

The gas line connection may be made of rigid

pipe, copper pipe or an approved

fl

ex connector.

(If you are using rigid pipe, ensure that the valve

can be removed for servicing.) Since some

municipalities have additional local codes it is

always best to consult with your local authorities

and the CAN/CGA B149 installation code.

For USA installations follow local codes and/or

the current National Fuel Gas Code, ANSI

Z223.1.

When using copper or

fl

ex connectors use only

approved

fi

ttings. Always provide a union so

that gas lines can be easily disconnected for

servicing. Flare nuts for copper lines and

fl

ex

connectors are usually considered to meet this

requirement.

Important: Always check for gas leaks with

a soap and water solution or gas leak detec-

tor. Do not use open

fl

ame for leak testing.

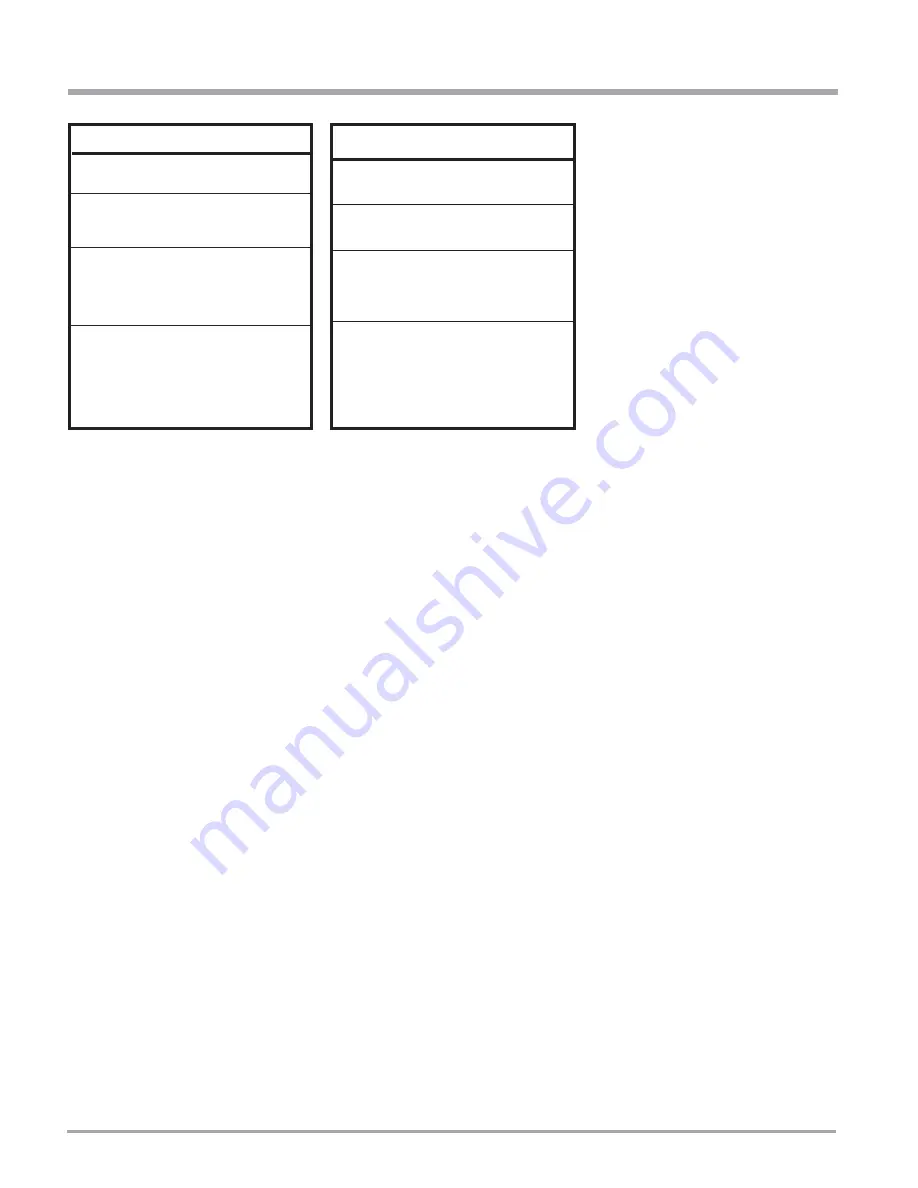

P36E-NG4 System Data

For 0 to 4500 feet altitude

Burner Inlet Ori

fi

ce Sizes:

#37

Max. Input Rating:

29,500 Btu/h

Min. Input Rating:

19,500 Btu/h

Supply Pressure:

min.5.0"

w.c.

Manifold Pressure

(High):

3.5"+/-

0.2"w.c.

Electrical

: 120 V A.C. System.

Circulation Fan

: variable speed 130 CFM.

Log Set

: Ceramic

fi

bre, 7 per set.

Vent System:

Simpson Dura-Vent Direct

Vent System or FPI Direct Vent System (Flex)

P36E-LP4 System Data

For 0 to 4500 feet altitude

Burner Inlet Ori

fi

ce Sizes:

#52

Max. Input Rating

28,500 Btu/h

Min. Input Rating

22,000 Btu/h

Supply Pressure

min.11.0"

w.c.

Manifold Pressure

(High)

10"+/- 0.2" w.c.

Electrical

: 120 V A.C. System.

Circulation Fan

: variable speed 130 CFM.

Log Set

: Ceramic

fi

bre, 7 per set.

Vent System:

Simpson Dura-Vent Direct

Vent System or FPI Direct Vent System (Flex)

INSTALLATION