Regency CI1200 / CI1250 Wood Cast Insert

23

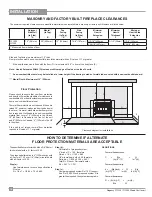

OPERATING INSTRUCTIONS

Overfi ring can cause extensive damage to your

stove including warpage and premature steel

corrosion. Overfi ring will void your warranty.

8)

Do not permit creosote or soot buildup in the

chimney system. Check and clean chimney at

regular intervals.

9)

Your Regency Insert can be very hot. You

may be seriously burned if you touch the insert

while it is operating. Warn children of the burn

hazard. Keep furniture and clothing away.

10)

The insert consumes air while operating, pro-

vide adequate ventilation with an air duct or

open a window while the insert is in use.

11)

Do not use grates, irons or other methods for

supporting fuel. Burn directly on the bricks.

12)

Open the draft control fully for 10 to 15 seconds

prior to slowly opening the door when refuelling

the fi re.

13)

Do not connect your unit to any air distribution

duct.

14)

Your insert should burn dry, standard fi rewood

only. The use of “mill ends” is discouraged as

this fuel can easily overheat your insert. Evi-

dence of excessive overheating will void your

warranty. As well, a large portion of sawmill

waste is chemically treated lumber, which is il-

legal to burn in many areas. Chemically treated

fi re logs also must not be burned in your insert.

15)

Do not store any fuel closer than 2 feet from

your unit.

16)

Do not burn salt drift wood as it will corrode

your unit and void the warranty.

17)

Do not strike or slam the glass door shut as

this may cause the glass to break.

18)

Do not operate the unit if the glass is broken or

missing. Do not operate the unit if the gasket-

ing is worn out and not sealing the door or the

glass.

It is very important to carefully maintain your insert,

including burning seasoned wood and maintain-

ing a clean stove and chimney system. Have the

chimney cleaned before the burning season and as

necessary during the season, as creosote deposits

may build up rapidly. Moving parts of your insert

require no lubrication.

ASH DISPOSAL

During constant use, ashes should be removed

every few days. Please take care to prevent the

build-up of ash around the start-up air housing

located inside the fi rebox.

DO NOT ALLOW ASHES TO BUILD UP TO THE

LOADING DOORS.

Only remove ashes when the fi re has died down.

Even then, expect to fi nd a few hot embers. Always

leave 1 to 2 inches of ash in the bottom of the

fi rebox. This helps in easier starting and a more

uniform burn of your fi re.

Ashes should be placed in a metal container with a

tight fi tting lid. The closed container of ashes should

be placed on a noncombustible fl oor or on the

ground, well away from all combustible materials,

pending fi nal disposal. If the ashes are disposed

of by burial in soil or otherwise locally dispersed,

they should be retained in the closed container until

all cinders have thoroughly cooled. Other waste

should not be placed in the ash container.

SOME SAFETY

GUIDELINES

1)

Never use gasoline, gasoline type lantern fuels,

kerosene, charcoal lighter fuel, or similar liquids

or chemicals to start or ‘freshen up’ a fi re in your

insert. Keep all such liquids well away from the

heater while it is in use.

2)

Never use alternate fuels such as charcoal

that have the possibility of generating carbon

monoxide.

3)

Keep the door closed during operation and

maintain all seals in good condition.

4)

Do not burn large quantities of paper in your

insert.

5)

Do not burn garbage or fl ammable fl uids.

6)

If you have smoke detectors, prevent smoke

spillage as this may set off a false alarm.

7)

Do not overfi re your insert. If the insert or its

fl ue baffl e begin to glow, you are overfi ring.

Stop adding fuel and close the draft control.

CREOSOTE

When wood is burned slowly, it produces tar and

other organic vapors, which form creosote when

combined with moisture. The creosote vapors

condense in the relatively cool chimney fl ue of a

slow-burning fi re. As a result, creosote residue

accumulates on the fl ue lining. When ignited, this

creosote can make an extremely hot fi re.

Removal for Cleaning etc.

Removal of your insert for cleaning purposes is

usually not required if a proper installation has been

done. In the event that removal is required, be sure

not to damage any parts needed for re-installation.

In most cases removal and replacement of the

baffl e system should allow full access for cleaning.

WARNING: Things to remember in case

of chimney fi re

:

1) Close draft control

2) Call the Fire Department

Ways to Prevent and

Keep Unit Free of Creosote

1)

Burn insert with draft control wide open for

about 15 minutes every morning during burn-

ing season. This helps to prevent creosote

deposits within the heating system.

2)

Burn insert with draft control wide open for about

10 - 15 minutes every time you add fresh wood.

This allows the wood to achieve the charcoal

stage faster and burns up any wood vapors

which might otherwise be deposited within the

system.

3) Only burn seasoned wood!

Avoid burning

wet or green wood. Seasoned wood has been

dried at least one year.

4)

A small hot fi re is preferable to a large smoul-

dering one that can deposit creosote within the

system.

5)

Check the chimney at least twice a month during

the burning season for creosote build-up.

6)

Have chimney system and unit cleaned by

competent chimney sweeps twice a year during

the fi rst year of use and at least once a year

thereafter or when needed.