18

15.2.2. REPLACEMENT OF A CRANK WITH BEARING

.

Replacing a crank is necessary when it is cracked or when the big end nuts start to come loose on a

regular base. Either the crank bearing, the crank bearing fitting or the big end pin holes in the crank

are damaged. Replace the crank / bearing as soon as possible, to avoid any more damage to other

parts, as follows:

1. Remove big end pin nuts IV (or II) from both big end pins connected to the crank.

2. Remove the big end pins, so that the big end can be swopped away. (Note; this will not happen

with the big end (pin) aside the gearbox.).

3. Remove the crank bearing covers III

4. Tap crank IV and bearing carefully sidewards out of the frame by hitting the crank in the centre

with a hammer.

5. Remove the bearing carefully from the crank.

6. After replacing the crank and/or bearing, replace the parts in the same sequence as they were

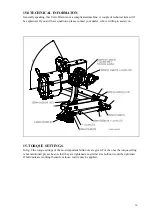

removed. Use loctite were indicated in fig.8.

7. If the crankshaft runs tight, see 15.2.3.

15.2.3 REMOVING THE CRANKSHAFT TENSION

.

If parts have been replaced on the crankshaft, the crankshaft may seem running tight. This is because

of possible tension in the crankshaft parts. It is necessary to remove these, as follows ,see fig.9.:

1. Tap the centre of the crank adjacent to the gearbox, alternately left and right.

2. Feel whether the crank moves and continue till the crank has nested.

3. Repeat this operation with the adjacent crank and continue this way till the crankshaft will operate

more smoothly.

@ After any repair on the crankshaft, the crankshaft nuts should be checked regularly, see 12.0

@ Don’t assemble the cranks at the wrong side of the machine. See the spare part part for the right

par t numbers.

15.3 ALIGNMENT OF AN ELEMENT

.

In the event that an element is no longer in line with the adjacent elements, the alignment can be

corrected as follows (see fig.8.):

-

Slacken the four bolts/nuts A, that connect the crankshaft to the element.

-

Slacken the two bolts B, that fix the element to the main frame.

-

Try to align the element by moving it sidewards, till it ligns up with the adjacent ones.

-

Start to tighten all bolts/nuts.

@ The element may be pushed out of line due to overload to the machine

@ When a crank is replaced, always realign the element, because if no additional tension is created in

the total element assembly.

@ Any pre-tension in the element assembly will shorten the bearing life and may damage other parts

as well.