14

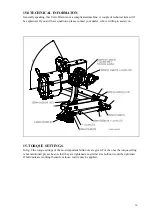

12.0 PROBLEM ANALYSIS

.

Machine vibrates

Crankshaft rotates irregular

Tough circumstances

Machine not at 90 degrees

PTO joint angles different

PTO joints not in line

Adjust working depth

Use thinner/ shorter tines

If dry, irrigate first

Solid/ hollow tines

Are bending/ breaking

Wrong tine

Tough circumstances

Quick wearing

Change tine, use shorter one

Use solids first before hollow to

break the soil

Adjust working depth

Use thinner/ shorter tines

If dry, irrigate first

Use solids first to break the soil,

Adjust tine angle setting

Front roller is not stable

On the ground

Wrong tines, too much resistance

Tough circumstances

Change tine size

Adjust working depth

Use other size tines

Adjust working depth

Irrigate first

Do job not in one pass

PTO breakage

Slip clutches slips often

Tubes are cracking

Check setting

Replace lining plates

Clean clutch internally

PTO angles too wide

Use the wheel kit

PTO angles not the same

Damage to draw rods

Bending/ breaking

Machine not at 90 degrees

Central bar bent

Bearing bushes worn

Tines hit the ground with reversing

Lift height not correct

Damage to the turf

Oval holes

Turf damage

Soil too wet

Change tine angle setting

Reduce forward speed

Adjust working depth

Use thinner tines

Tine not tight in tine

holder

Tough circumstances

Use other tines

Grind flat area to tines

Adjust the tine angle setting

Crankshaft problems

Big end nuts slacken

Solve vibration, see vibration