13

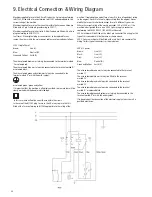

Fig.4.5

Depth Scale

4. Machine Assembly

4.1 Fixing the in-feed table

1. Remove the four socket head cap screws from

table cover rails already fitted and remove the

cover rails

Fig.4.1

.

2. Take the in-feed depth of cut adjustment

bar and remove the collar and sprung washer

Fig.4.2

.

3. Thread the bar through underside of table

then re-fit and secure collar

Fig.4.3

.

4. Offer the table up to the machine whilst

threading the depth of cut adjustment bar into

the spacer shaft

Fig.4.4.

5. Fit the infeed table into position and wind the

depth of cut bar until the uppermost line on the

depth scale is registered with the line on the

side of the table

Fig.4.5

. Re-fit and secure the

table cover rails,

Fig.4.6.

these rails should not

be fully tightened as the table needs to slide up

and down in order to adjust the depth of cut. As

a guide fully tighten the socket head cap screws

then unscrew by 1/4 turn.

4.2 Fixing the thicknessing dust

extraction outlet

Moving round to the opposite side of the

machine, locate the slotted extrusion and place

the extraction outlet into position

Fig.4.7

.

Secure this outlet into slot using 4 self tapping

screws and washers

Fig.4.8

4.3 Fixing the outfeed table

1. Place the outfeed table over the lugs on the

planer body and lock the table in place with the

levers.

Fig.4.9.

4.4 Table adjustment

Table adjustment is not necessary at this

stage. See the table adjustment part of the

maintenance section.

Fig.4.1

Fig.4.2

SOCKET HEAD

CAP SCREW

TABLE COVER

RAILS

COLLAR

Fig.4.3

COLLAR & SPRUNG

WASHER

Fig.4.4

SPACING SHAFT

Fig.4.6

SOCKET HEAD CAP SCREW

TABLE COVER

RAIL

DEPTH OF

CUT BAR

DEPTH SCALE

Fig.4.7

Fig.4.8

Slotted

extrusion

Slot

Self tap screw

& washer

Fig.4.9

Locating

Lugs

Locking

levers

SPRUNG WASHER

Summary of Contents for PT260

Page 28: ...28 11 Parts Diagrams Stand Wheel Kit ...

Page 29: ...29 11 Parts Diagrams cont ...

Page 30: ...30 11 Parts Diagrams cont ...

Page 34: ...34 ...

Page 35: ...35 ...