25

10. Maintenance - cont.

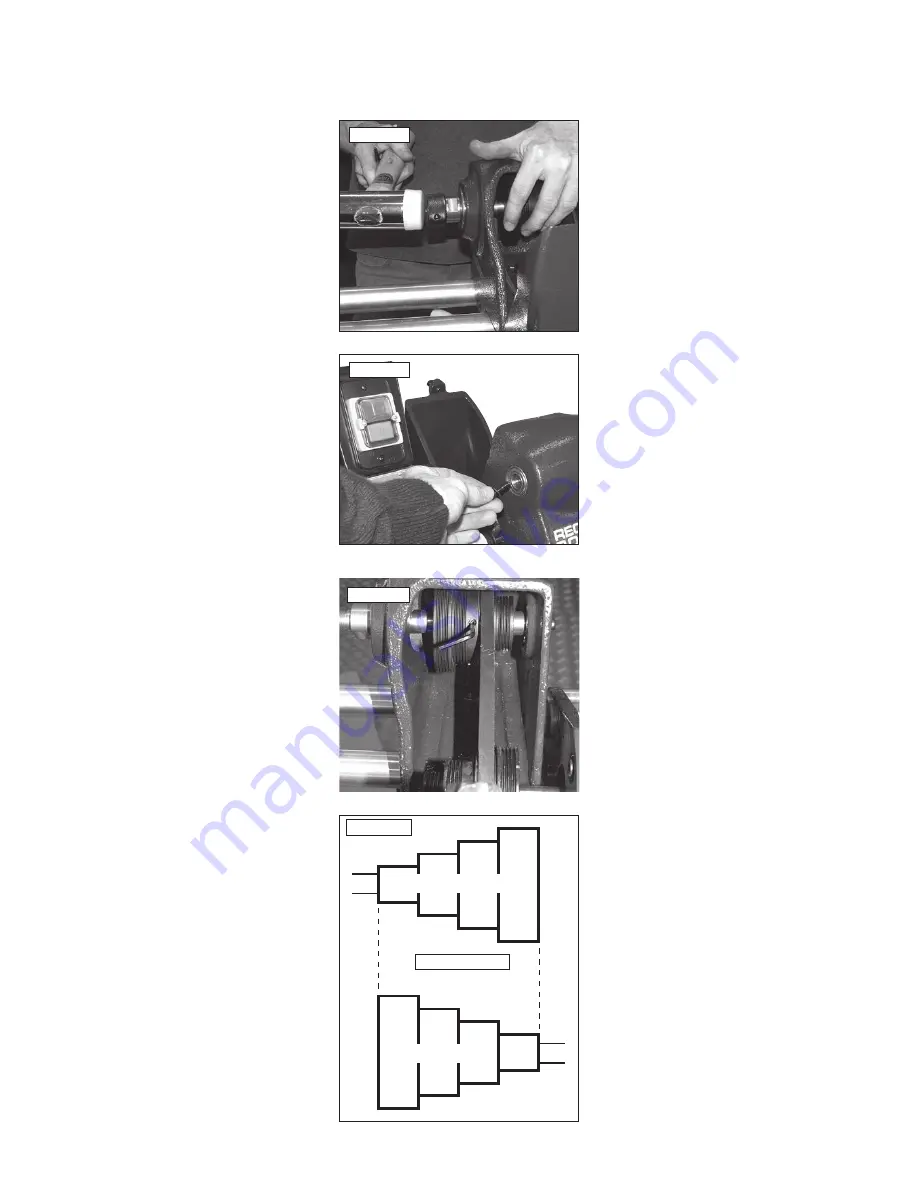

14. Slide the spindle back into the headstock

and into the pulley. Ensure that the drive belt is

fitted around the spindle pulley,

Fig.10.11

.

15. While the spindle and bearing is being

knocked into place, one hand must be used to

keep rotating the spindle a 1/4 turn at every

strike of the mallet,

Fig.10.12

. This ensures that

the spindle seats correctly in the bearings. You

will feel the spindle seat against the headstock

and there will be a dull thud as the mallet

strikes the thread protector. This stage is now

complete.

16. Replace the Allen bolt and large washer into

the back of the headstock. Do not over tighten

this, the bolt should only be turned until finger

tight,

Fig. 10.13

, then apply a 1/4 of turn with

an Allen key.

17. If not already done the drive belt should now

be placed on the motor pulley and the spindle

pulley adjusted so as to line up with the motor

pulley, finally tighten the two grub screws into

the spindle pulley,

Figs 10.14

&

10.15

.

18. Re-tension belt by applying slight downward

pressure on motor then tighten the tension lever.

With the belt in position and the headstock

cover replaced the machine should be run for a

little time to enable the belt to bed in.

Ensure that the lathe is switched off, the

machine is unplugged and all tools and

other items are clear of the machine.

Make sure that the headstock cover is

firmly locked in position before starting

the lathe.

Fig.10.13

Fig.10.12

Fig.10.14

Fig.10.15

Pulleys aligned

Spindle Pulley

Motor Pulley