PRO-SERIES ATHENE - VARIABLE RATE DRILL CONTROL

22

5.1.1 Overriding the VRT application rate

You can vary the actual application rate at any time using the keys.

The target rate display will flash until you press to return to the target rate.

5.1.2 Stop a VRT job

To stop running a job, simply press the 'STOP' key on the data logging screen. The job summary is appended

to the work record file on the data module, and saved to the internal memory.

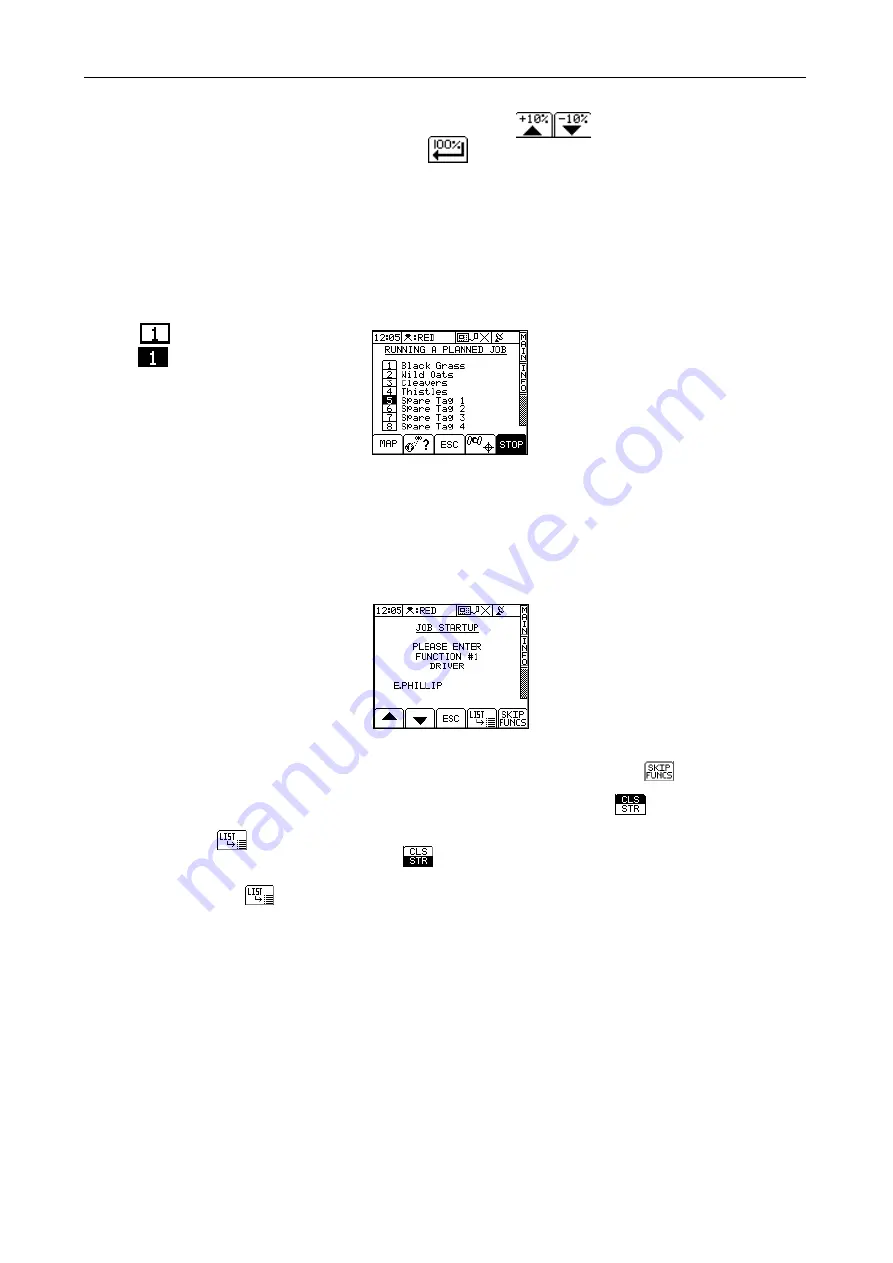

5.1.3 Tagging

During application, you can log the presence of up to eight different features in the field, e.g. different weed

infestations, pest damage etc. To switch a tag on or off, simply press the appropriate number key.

indicates the tag is off

indicates the tag is on

Tags 1 to 4 are preset for Blackgrass, Wild Oats, Cleavers and Thistles. You can however, edit the tag names

from the 'GENERAL PF SETUP menu (section 4.5.2).

5.1.4 Extended Data Functions

Dynamic log files and simple job summaries can include up to 12 additional data. All 12 data items can be

user-defined to suit individual requirements e.g. Operator, Wind Speed, Air Temperature, Growth Stage,

Product etc. Entering extended data is optional.

If you do not want to change the default value, simply press the ENTER key to accept it, and then the next 'F'

function appears. If you do not need to programme any of them, simply press at any time to start

logging.

NOTE: If a function on the 'Function Names/Values' page in the setup menu is set to (Clear Store), no default

value will appear on the 'Job Startup' page or be logged for that function, unless the operator manually selects a

value via the key.

Likewise, If that function a function is set to (Store), then when a new job is started, the value set for the

previous job will appear on the 'Job Startup' page. It then becomes the responsibility of the operator to change

the value via the key if so desired.

Refer to section 4.5.2 to programme function names / values.

5.1.5 Display vehicle track - "MAP"

From the data logging screen, press the "MAP" key. The screen displays the real time position of the vehicle

(the "+" cursor), and the vehicle track for the last 100 logged data points.

The screen also displays the latitude and longitude in decimal degrees, and the number of points. As the

vehicle proceeds from the start of the job, the screen plots and automatically zooms out to display up to a

maximum of 100 logged data points. Beyond this, as the job progresses, the display pans in the direction of

movement to keep the previous 100 data points on screen.

Press the 'RESET' key to start the plot again from the current position. If you selected the "LOG TREATMENT"

option from the data logging screen, the track data is saved to a dynamic logging file on the data module.