50

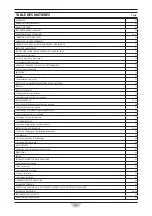

HYDRAULIC SYSTEM “1/2” (FIG.13)

The hydraulic system that rotates the brushes, lifts and opens the Refuse container is driven by one gear pump that

is controlled by the internal combustion engine. The brush rotation is controlled directly by revolving motors con-

nected in series. The control of each function is given by a three element control valve 1.

Maintenance and adjustment of the hydraulic system

The hydraulic system must have a working pressure of 90 bar with all the brushes lowered and a max. pressure of 150

bar adjustable by a closed circuit through the pressure relief valve 2 set on the control valve. To check the pressure,

proceed as follows:

•

Disconnect pipe 3 from the connection 4 on the control valve and reconnect it to the pressure gauge line 5.

•

Screw the pipe of the pressure gauge 5 to the connection 4.

•

Move the lever 6 to right or left as shown by the arrows.

•

Bring the engine to top rpm and check that the pressure gauge does not read more than 150 bar. If this is not

the case, adjust the pressure register 2.

The whole hydraulic circuit is protected by an oil fi lter 7 on the suction side. The fi lter is cartridge type. With a new

motor sweeper, the hydraulic oil cartridge 8 should be changed after 20 hours of work.

N.B. The check is carried out when the oil is hot using dipstick 8 placed on hydraulico oil tank 10, every 40

hours of work.

Before changing the cartridge, turn off the hydraulic oil tap 9 and open it again at the end of the check.

A = Tap, opened

C = Tap closed

When a new cartridge is inserted, make sure that it is exactly the same as the one being removed.

Control valve

The control valve unit 1 includes three components. Each of these elements has a cursor which is controlled by a lever.

1

2

3

4

5

6

7

9 10 8

A

A

C

C

Summary of Contents for 31.00.127

Page 2: ...2 ...

Page 3: ...3 ITALIANO Pagina 4 ENGLISH Page 32 FRANÇAIS Page 61 NEDERLANDS Pagina 90 ...

Page 27: ...27 SCHEMA IMPIANTO ELETTRICO FIG 20 15 N1 P codice schema 1 9 12044 ...

Page 32: ...32 ENGLISH ...

Page 56: ...56 WIRING DIAGRAM FIG 20 15 N1 P codice schema 1 9 12044 ...

Page 61: ...61 FRANÇAIS ...

Page 85: ...85 SCHÉMA DE CÂBLAGE FIG 20 15 N1 P codice schema 1 9 12044 ...

Page 90: ...90 NEDERLANDS ...

Page 114: ...114 SCHEMA ELEKTRISCH SYSTEEM FIG 20 15 N1 P codice schema 1 9 12044 ...