The flue system used on this appliance must be provided

by AGA and must be installed in accordance with the

instructions and standards.

A maximum flue of 5 metres and 5 bends can be used

(including horizontal length on the terminal).

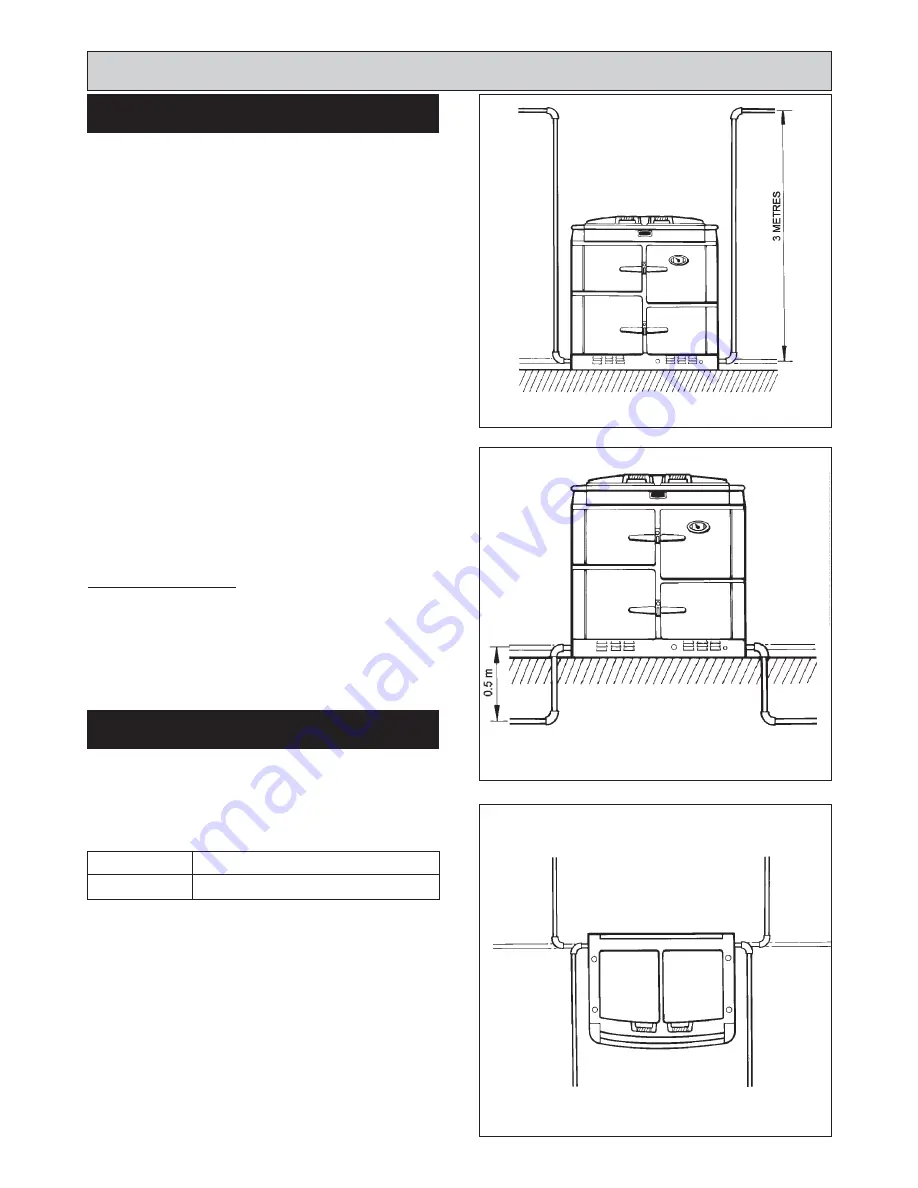

Any upwards vertical runs must be immediate to the

appliance to a maximum of 3 metres. (See Fig. 6)

Downwards vertical runs must be no more than 0.5

metres. (See Fig. 7)

Flue can be positioned to the rear or front of appliance via

1 bend. (See Fig. 8).

Horizontal runs must be as level as possible.

Care must be taken on mounting the terminal and routing

the flue:-

a. Damage to damp proof course

b. Height above ground

c. General terminal locations (See Fig. 9)

Where the flue passes through combustible material a

minimum of 10mm clearance must be maintained around

the flue pipe and insulation sleeve.

General Requirements

The flue pipe must be adequately supported using the

brackets specified.

The flue pipe must be insulated (supplied).

All joints should be sealed using the sealant provided.

The appliance can only be installed in a room which

meets the ventilation regulations in force. But, in any

event the room must have a permanent vent with a

minimum free air area, see below.

IMPORTANT: THE LOUVERED AIR INTAKE AT THE

BOTTOM FRONT OF THIS APPLIANCE MUST BE

KEPT CLEAR OF ANY OBSTRUCTIONS.

9

Site requirements

FLUE SYSTEM

AIR REQUIREMENTS

XTG

35 cm

2

MODEL

MIN. AIR REQUIREMENT

FIG. 6

FIG. 7

FIG. 8

DESN 514115 B

DESN 514116 B

DESN 514114

Summary of Contents for XT

Page 20: ...20 Wiring Diagram FIG 21 WIRING DIAGRAM APPLIANCE ...

Page 22: ...22 ...

Page 23: ...23 ...