Warranty Statement 45

Warranty Statement

L-Bar Sealer Tunnel Combo Sealing Machine

Warranty Statement

Eastey Enterprises warrants that all of the products it ships will be in good working order

and free from defects in material and workmanship and will conform to the published

specifications for that product.

Warranty Period

Drive motor(s):

1 year

All other parts:

1 year (Except for moving parts which are subject to normal

wear, tear and replacement which are warranted to be free

from defects in material and workmanship.)

Shipping Policy

Customer pays all incoming shipping. If the item is defective and under warranty,

Eastey pays return shipping charges for least costly method. If expedited shipping is

desired, customer must furnish his shipping account and shipping fees will be charged

to that account.

Warranty Verification

If you conclude that a product may be defective and may be covered by warranty,

obtain a Return Material Authorization number by calling our technical support number

(toll free at 1-800-835-9344, or 763-428-4846 or Fax: 763-795-8867) or e-mail:

[email protected]. Based on the recommendation from Eastey technical support,

replacement components may be shipped out via UPS Ground or similar method. If

expedited shipping is desired, customer must furnish their shipping account and

shipping fees will be charged to that account. Customer is required to return the

defective component to Eastey. If, after 30 days, Eastey

hasn’t received the defective

component, the customer will be invoiced for the replacement component. If the

returned component is found to not be eligible for warranty, Eastey will contact the

customer and the customer will be invoiced for the replacement component.

Warranty Eligibility

The warranty provided by Eastey Enterprises, Inc. is only to the original buyer.

Limited Warranty

THE ABOVE WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, WHETHER EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

AND NONINFRINGEMENT.

Disclaimer of Damages

REGARDLESS OF WHETHER ANY REMEDY SET FORTH HEREIN FAILS OF ITS

ESSENTIAL PURPOSE, IN NO EVENT WILL EASTEY ENTERPRISES, INC. BE

Summary of Contents for Eastey Value Series

Page 2: ......

Page 4: ......

Page 6: ......

Page 29: ...Electrical Schematic 29 Electrical Schematic...

Page 30: ...30 Electrical Schematic Electrical Schematic Continued...

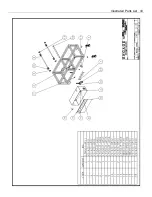

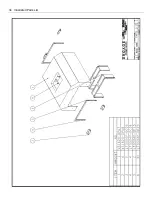

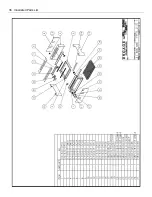

Page 31: ...Illustrated Parts List 31 Illustrated Parts List...

Page 32: ...32 Illustrated Parts List...

Page 33: ...Illustrated Parts List 33...

Page 34: ...34 Illustrated Parts List...

Page 35: ...Illustrated Parts List 35...

Page 36: ...36 Illustrated Parts List...

Page 37: ...Illustrated Parts List 37...

Page 38: ...38 Illustrated Parts List...

Page 39: ...Illustrated Parts List 39...

Page 40: ...40 Illustrated Parts List...

Page 41: ...Illustrated Parts List 41...

Page 42: ...42 Illustrated Parts List...

Page 43: ...Illustrated Parts List 43...

Page 48: ......

Page 49: ......