R A M S E T

z

R A M S E T

z

R A M S E T

RA

MS

ET

z

RA

MS

ET

z

RA

MS

ET

- 9 -

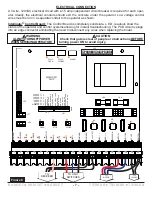

DIP SWITCH B5: “LAG DELAY”

Lag on Close

One second lag on close

DIP SWITCH B6: “LAG MODE”

Lag on Open

One second lag on open

DIP SWITCH B7: “REVERSE LOGIC”

DIP FUNCTION

‘off’ Left hand operation – standard installation

‘on’ Right hand installations – Reverses motor & limit switches

without having to move any wires.

DIP SWITCH B8: “SLAVE MODE”

Master/slave

DIP FUNCTION

‘off’ Master mode – single gate operation. All peripheral devices

are to be connected to the master operator.

‘on’ Slave mode – used to synchronize operation between two

gates. Commands are received from the master through a

3-wire, shielded cable.

TERMINAL STRIP CONNECTIONS

CONTROL INPUT DESCRIPTIONS

AC Hot & Neutral

– 110 or 220 VAC to power the operator.

Voltage is predetermined at factory and cannot be changed

by the installer or technician.

Close

– Closes the gate. Used with three button stations or

pushbuttons. Becomes active with a closed contact to com-

mon.

Exit

– Opens the gate. Used with loop detectors, photo

eyes, keypads, phone entry systems, three-button sta-

tions…etc. Becomes active with a closed contact to com-

mon.

Firebox/SOS

– Opens the gate. Used with fire dept. key

switches & controls. Becomes active with a closed contact

to common, maintained or momentary depending on dip

switch B2 (see “dip switch features”).

Stop

– Stops the operator from moving. To be used as a

non-contact sensor such as a photo-beam, edge connector

or a three-button station. Becomes active with an open con-

tact to common when dip switch A7 is in the ‘on’ position

(see “dip switch features”).

Radio

– Operation depends on dip switch B3 (see “dip

switch features”). Used with an RF receiver or pushbutton.

Becomes active with a closed contact to common.

SAFETY INPUT DESCRIPTION

Limit 1 & Limit 2

– Depending on dip switch B7 (see “dip

switch features”), stops the motor from moving in one direc-

tion. These wires are preset in factory and should not be

moved. Becomes active with a closed contact to common.

Phantom

– Keeps the gate open when the open limit switch

(A or B) is activated. Used with loop detectors. Becomes

active with a closed contact to common.

Rev Loop

– Stops the gate from closing. If the gate is open,

it holds the gate open. If the gate is closing, it stops and

reopens the gate. If the gate is closed, the gate will remain

closed. The function can be altered with dip switch B4 (see

“dip switch features”). Used with loop detectors, photo eyes,

safety edges…etc. Becomes active with a closed contact to

common.

OUTPUTS

Mag

(

+

)

& Mag

(

-

)

Supplies 24VDC to a magnetic lock when gate is closed. If

gate is not closed then no power is supplied. Leave open if

not used.

Motor 1 & Motor 2

– Supplies power to the motor. Direction

depends on dip switch B7 (see “dip switch features”). These

wires are preset and connected in the factory and should not

be moved.

24V Rect.

– Provides a rectified 24VDC for peripheral

accessories.

Solenoid

– Sends 110 VAC to a solenoid or other mechani-

cal lock. Leave open if not used.

OTHER CONNECTIONS

Contact Closure Relay Outputs

Three separate isolated form-C relay outputs are provided.

Each relays contact is rated at 125VAC, 2 amps.

1.

Alarm – When ERD is triggered twice, before reaching a

fully closed or fully opened position, 24VDC is supplied

for 6 minutes and the control board will not accept any

commands. After the 6 minutes the 24VDC is removed

and the board resets to normal operation.

2.

Triggers relay when gate is fully opened. Used with indi-

cator lights, buzzers, beepers, misc. voltage magnetic

locks…etc.

3.

Triggers relay when gate is fully closed. Used with indi-

cator lights, buzzers, beepers, misc. voltage magnetic

locks…etc.

Note

: if both B5 &

B6 are 'on', there

will be NO lag on

the open or close.