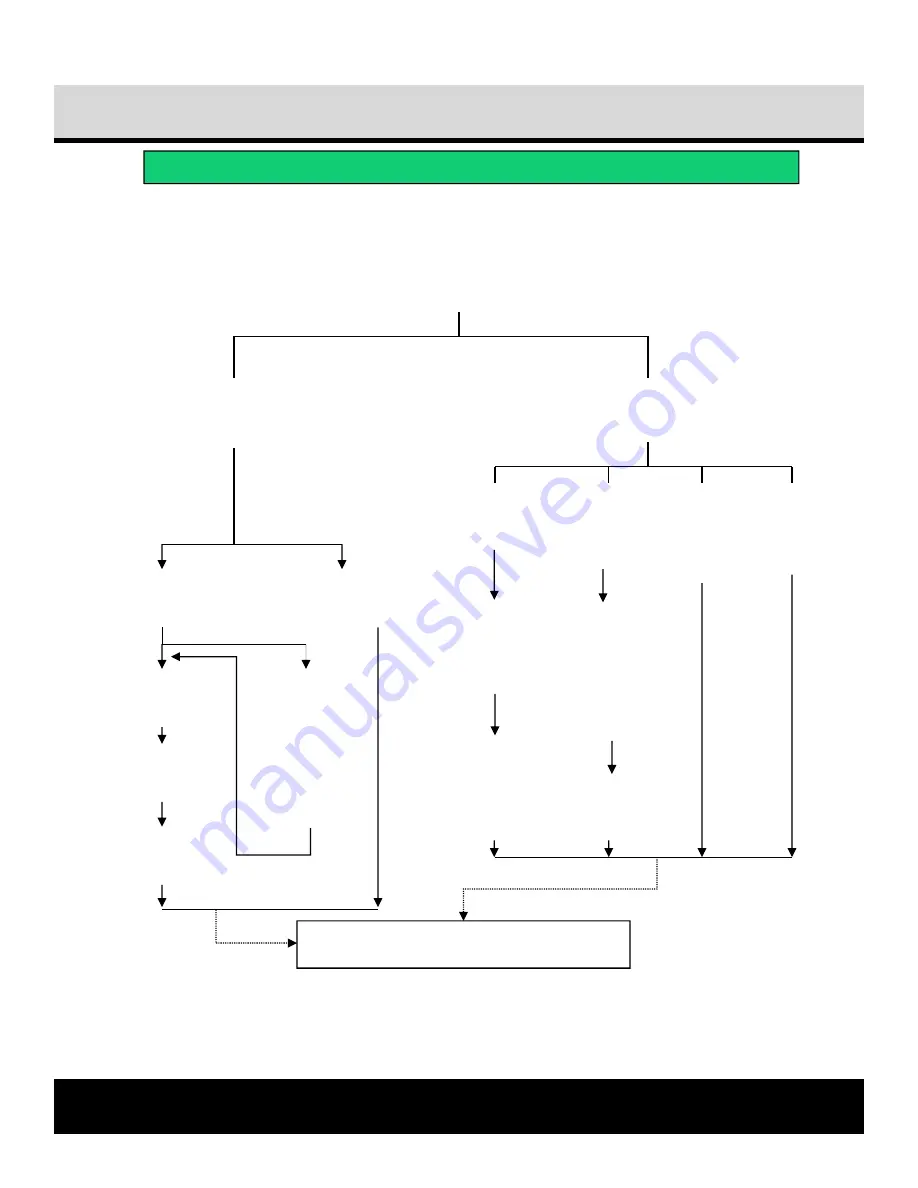

CONTINUOUS OR TOO FREQUENT BACKFLUSHES

PRESSURE BELOW THE MINIMUM

REQUIRED.

See section “Technical Data”

from the Filtration Equipment Manual

PRESSURE EQUAL OR ABOVE THE

MINIMUM REQUIRED.

See section “Technical Data”

INCORRECT

PROGRAMMING

OF THE

CONTROLLER

ACTIVATE A

BACKFLUSH AND

CHECK THE PRESSURE

IN THE OUTLET

MANIFOLD

TOO SHORT TIME

BETWEEN

BACKFLUSHES. Rise

the value. See section

“Time between

backflushes phases”

from the Control Unit

Manual

INFLUENT

WATER QUALITY

LOWER THAN

THE ESTIMATED

RUNNING FLOW

HIGHRER THAN

DESIGN

TOO SHORT OF

BACKFLUSH

DURATION. Raise the

value. See section

“Backflushing time of

each station” from the.

PROBLEM

WITH THE

DIFFERENTIAL

PRESSURE

GAUGE

CHECK THE

REGULATED

VALUE IN THE

DIFFERENTIAL

PRESSURE

GAUGE. See

section “Differential

Pressure Gauge

Delay” from the

Control Unit Manual

CHECK

CONNECTIONS OF

THE DIFFERENTIAL

PRESSURE GAUGE

If the problem persists or you have any

doubt, contact your distributor.

DOES IT HAVE A

MASTER VALVE?

CHECK THE PUMP

SYSTEM WHEN

BACKFLUSHING

THE MASTER VALVE

DOES NOT WORK

PROPERLY Check the

components of the

sustaining valve

according to section

Maintenance

Instructions

from the

Manual and the

regulation of the Relief

Pilot according to

section

Operating

Instructions

from the

Manual

CHECK THE

INSTALLATION

(POSSIBLE LEAKS)

INAPPROPRIATE

MEASURE OF THE

FEEDING PUMP

INLET FLOW

SUPERIOR TO THE

ONE ESTIMATED IN

DESIGN

YES

NO

YES

NO

19

Summary of Contents for HDF 1X2

Page 1: ...1X2...