17

Knocking

noise

No connection

with the fuel

hose

Contact

Bad fuel

replace the fuel

Deposits on

combustion

chamber

Clean up

Moving parts are

scored and worn

Check and

replace

3. The engine stops

Problem

Reason

Solution

The engine

stopped

suddenly

Spark plug

cable is loose Connect it firmly

The piston is

blocked

Replace the

piston and fix it

The spark

plug is burned Clean it

Fuel runs out Load fuel

The engine

stops slower

Carburetor is

blocked

Clean it

Vent the tank

is half blocked Clean it

The fuel is

mixed with

water

change fuel

4. The engine stops hard

Problem

Reason

Solution

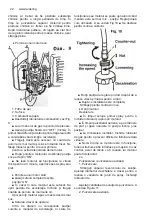

Throttle lever

is in the down

position, but

the engine still

running

The sting of

gas is too

short (low

speed is high)

Adjust the cable

as described in

Fig. 10

5. Spraying

Problem

Reason

Solution

There is not

absolutely

chemical

spraying or it

interrupts

Off the control

valve or nozzle

is clogged

Clean it

The mixture

tube clogged

Clean it

No pressure or

pressure is low

in the scheme

Tighten the lid of

the tank and turn

the two wing nuts

securely

Leakage of

chemicals

Fragmentary

plate is

inserted

incorrectly

Put it right

Some of the

connections

are loose

Tighten

6. Aerial spraying

Problem

Reason

Solution

Dust not

discharge or

discharge is

intermittent

The flap of the

dust may not

open

Adjust the

valve cable

Powder or

granules are

mixed with

impurities

Clean it

Powder or

granules have

become lumps

Crush clods

Wet granules or

powder

Dry it

The flap of the

dust does not

work well

The flap of the

dust can not be

closed

Настроте

жилото на

клапата

The flap of the

dust is blocked

by a foreign

body

Clean it

Expiry of dust

Bracket on the

bottom of the

chemical tank is

loose

Tighten

Sealing rubber

seal dusty

saucer damaged

Replace with

new

Release

of dust is

uncontrollable

Valve control

device is not

working properly

Fix it

OPERATION AND CARE FOR LONG LIFE OF

MACHINE

1. Operation or spraying

• After spraying clear any residue or dust from

the solution tank. Wash the tank and all other parts.

• After aerial spraying or dispersing granules,

clear plate and sprayed inside and outside the tank.

• After work loose plate of the chemical tank.

• After cleaning the machine left the engine

running at minimum power for 2-3 minutes.

2. Operation of the fuel system

• Fuel mixed with water or dust is a major cause

of engine problems h, so the fuel system should be

cleaned frequently.

• If the remaining fuel stays in the tank and

carburetor long time, it can kleyasa and clog the

fuel system. This is the reason the engine does not

work well. Once the machine has not worked one

week all the fuel must be drained.

3. Operation of the air filter and spark plug