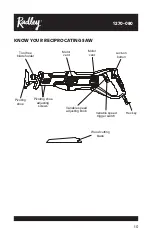

12

1270-080

VARIABLE SPEED TRIGGER SWITCH – cont’d

2. To increase the speed of the saw,

squeeze the switch trigger harder.

NOTE: When the switch trigger is

squeezed fully, the saw will run at its

maximum speed.

3. To turn the saw OFF, release the

switch trigger.

VARIABLE SPEED ADJUSTING KNOB

The maximum speed of the saw can be

controlled by the variable speed adjusting

knob (2) (Fig 4).

1.

To allow the trigger to be fully depressed

allowing the saw to operate at its fastest

speed, rotate the variable speed control

knob downward (3) as far as possible.

2. To limit the amount the trigger can be

depressed, and to control the maximum

speed of the saw, rotate the variable

speed adjusting knob upward (4).

NOTE:

The further the knob is rotated

upward, the slower the maximum speed

of the saw will become.

LOCK-ON BUTTON

Your reciprocating saw is equipped with a

lock-on feature, which is convenient when

continuous cutting for extended periods of

time is required (Fig. 5). To lock the switch

ON, depress the trigger switch, push in

and hold the lock-on button (5) located at

the left side of the handle, then release the

trigger. Release the lock-on button and your

reciprocating saw will continue running. To

turn the reciprocating saw OFF, depress and

release the trigger switch to release lock.

NOTE:

The lock-on button will only function

when the saw is running at full speed.

MATERIALS YOU CAN CUT

This reciprocating saw is a versatile tool that

allows you to cut many different types of

materials. Some of these materials include:

Wood products such as lumber,

hardwood, plywood, composite board,

and paneling

Drywall

Fiber board and plastic

Metals, such as pipe, steel rods, sheet

steel, aluminum, brass, and copper.

NOTE:

There are many different types of

blades available. Generally, there are metal

cutting blades (fine teeth) and wood cutting

blades (coarse teeth). Use the correct blade

for your application. The packaging on the

blade will indicate the type of materials each

blade is designed to cut.

ASSEMBLY AND OPERATING

(continued)

Fig. 3

1

Fig. 4

2

3

4

5

Fig. 5