17

6 Amp Reciprocating Saw - Owner's Manual

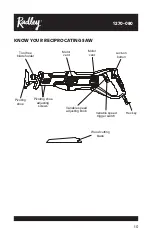

PARTS LIST

WARNING:

When servicing, use only original equipment replacement parts. The use of any other

parts may create a safety hazard or cause damage to the reciprocating saw.

Any attempt to repair or replace electrical parts on this reciprocating saw may create

a safety hazard unless repairs are performed by a qualified technician. For more

information, call the Toll-free Helpline, at 1-866-349-8665.

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

1190030061 Cord set

1

2

6140020012 Hex key

1

3

3140010053 Cord sleeve

1

4

4030010099 Tapping screw ST3.9*14

2

5

2030050002 Strain relief

1

6

1061010013 Switch

1

7

3011110016 Housing

1

8

4030010106 Tapping Screw ST3.9*19

10

9

3150060001 Brush holder sleeve

2

10

2030070004 Brush holder

2

11

1230010122 Carbon brush

2

12

4010010053 Bearing 607 2RS

1

13

1010110015 Rotor

1

14

1020110013 Stator

1

15

3150010029 Fan

1

16

2030030260 Fixed plate

1

17

4010010054 Bearing 6000 2RS

1

18

4030010106 Tapping screw ST3.9*19

2

19

3150070096 Gear box

1

20

4030010116 Tapping screw ST3.9*30

1

21

4060010022 Nut

2

22

2010150055 Reciprocating lever support

1

23

2030160149 Clamping plate

1

24

3150240029 Bearing washer

2

25

4030010192 Tapping screw ST5*25

2

26

3140080045 Rubber boot

1

27

3150160209 Fixed frame

1

28

4020080011 Adjusting screw M5*14

2

29

1150020092 Pivoting shoe assembly

1

30

3011110016 Housing

1

31

4020080011 Adjusting screw M5*14

1

32

4040030003 Spring washer ø5

1

33

4040010009 Bearing washer

1

34

4010010054 Bearing 6000 2RS

1

35

4010010081 Bearing 6201 2RS

1

36

2040040089 Spindle

1

37

2040080028 Big gear

1

38

2040220035 Roller

1

39

1150010044 Plunger assembly

1

40

2030030262 Clamping plate

1

41

6060030005 Blade

1

42

2030030261 Top cover

1

43

4030010249 Tapping screw ST5*14

4