Radijator Inženjering d.o.o, 36000 Kraljevo, Živojina Lazića - Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150, http://www.radijator.rs

e-mail: [email protected]

60

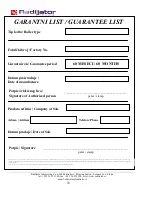

Figure 13. Upper and lower doors open and primary air flap open

15.

After this, it should be possible to fire up the boiler.

16.

When the flame is formed in the firebox, the upper door needs to be closed and the lower door

need to stay slightly open, so that the flame could reach the highest possible amount of fuel.

17.

When the flue gas temperature probe detects the temperature required for the boiler to enter the

operating mode (burning), the lower door has to be closed. The lower door should not be

opened again during the entire burning process. Lower door should be opened only after the

burning process is complete, i.e. when the boiler needs to be cleaned.

18.

It is necessary to move the flue outlet flap from the locking position, i.e. move the handle

towards the flue outlet, and then the flame would move downwards to the draft slot and achieve

pyrolysis.

19.

After the initial stacking (while the boiler is still in the burning phase), refill the firebox with

fuel. At this point it is necessary to pull the flue outlet flap towards you and lock it in this

position, thus opening the flue outlet and allowing the flame to go directly into it. The upper

door should be opened in a way that you first hold it slightly open and after several seconds start

with the refilling. The firebox should be refilled quickly to avoid excessive flue gas

temperatures. After the refilling of the firebox, the upper door needs to be closed and

immediately after this we can move the flue outlet flap from the locked position into the closed

position. After this, the pyrolysis process runs without interruptions.