Connection and termination resistor

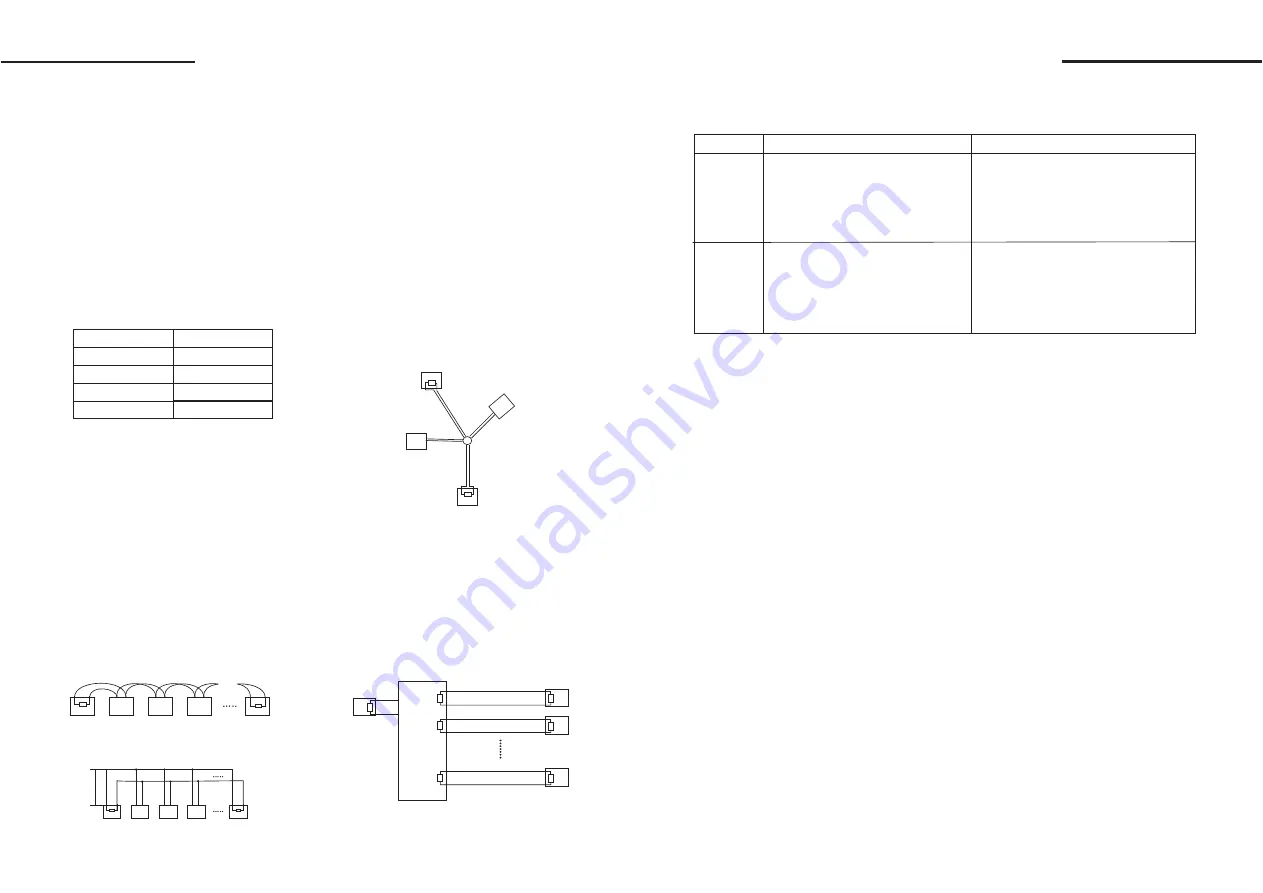

The Rs485Bus standards require a daisy-chain

connection between the equipment. There must be

termination resistors with 120

Ω

(as the picture 9.4

-1). Please refer to picture 9.4-2 for simple

connection. D should not exceed 7m.

8.2 RS485Bus basic knowledge

120

Ω

1# 2# 3# 4# 32#

Picture 9-4.1

120

Ω

2400bps

4800bps

9600bps

1800m

1200m

800m

Baud rate

Max distance

19200bps

600m

As specified by Rs485 standard, Rs485 Bus

is of half-duplexed data transmission cables with

characteristic impedance as 120

Ω

. The maximum

load capacity is 32unit loads(including main

controller and controller equipment)

Characteristics of Rs485 Bus

Transmission distances of Rs485 Bus

When user selects the 0.56mm(24AWG) twist

pair wires as data transmission cable, the max

theoretical transmitting distance are as follows:

If user selects thinner cables, or installs the

dome in an environment with strong electroma-

gnetic interference, or connects lots of equipment

to the Rs485Bus, the max transmitting distance

will be decreased. To increase the maximum

transmitting distance, do the contrary.

120Ω

1# 2# 3# 4# 32#

D

A+

B-

A+

B-

Picture 9.4-2

120Ω

Problems in practical connections

In some circumstances user adopts a star

configuration in practical connection. The

termination resistors must be connected to

the two equipment 1# and 15# in picture 9.4-3.

As the star configuration is not in conformity

with the requirements of RS485 standards,

problems such as signal reflections, lower

anti-interference performance arise when

the cables are long in the connection. The

reliability of control signals is decreased

with the phenomena that the dome does not

respond or just responds at intervals to the

controller, or does continuous operation

without stop.

1#

32#

15#

6 #

Mai n c ontroller

Picture 9.4-3

120

120

In such circumstances the factory reco-

mmends the usage of RS485 distributor.

The distributor can change the star config-

uration connection to the mode of connection

stipulated in the RS485 standards. The new

connection achieves reliable data transmi-

ssion (Refer to Picture 9.4-4).

RS485 Distributor

B-

1#

2#

3#

120

Ω

120

Ω

120

Ω

A+

120

120

120

Picture 9.4-4

1 7

Trouble

Possible cause

Solution

Dome can

do self-

testing

but can

not be

controlled

The dome can

be controlled

but the opera-

tion is not

smooth

1. Chage the address and baud rate of contro-

ller or dome

2. Adjust the + and -connection of Rs485

3. Make sure the connections are fully seated

4. Change RS485 Bus wires

1. Secure the connection

2. Replace RS485 bus wires

3. Add termination resistors to the

system

4. Install RS485 distributor

RS485Bus troubles shooting

1. The address and baud rate setting

of dome are not in conformity with

those of controller.

2. The + and - connection of RS485

Bus is incorrect

3. Bad connection

4. There are circuit in the RS485

Bus.

1. The RS485Bus is not in good contact with

the connectors

2. One wire of RS485bus is broken

3. The dome is very far from controller

4. There are two many domes connected in the

system

1 8

Appendix

Appendix

CALL+”N”+PRESET Show preset

SET+”N”+PRESET Save preset

CALL+”95”+PRESET Enter menu

CALL+”94”+PRESET Restart

CALL+”92”+PRESET Set scan1 Left limit

CALL+”93”+PRESET Set scan1 Right limit

CALL+”97”+PRESET Run scan1

CALL+”99”+PRESET

CALL+”62”+PRESET Open IR LED(manual state)

CALL+”63”+PRESET Close IR LED(manual state)

CALL+”98”+PRESET Run tour1

Run scan1

9.Shortcut key: