QR-25 Series

Quincy Compressor

52201-107, December 2012

28

3501 Wismann Lane, Quincy IL - 62305-3116

*Not applicable to models without oil pumps.

Pix 1068

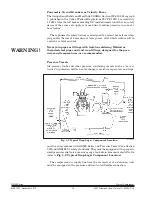

Fig. 5-4

Compressor Directional Ar-

rows

OIL RETURN PORT

FROM THE OIL FILTER

COUNTERSUNK

PIPE PLUG

OIL SUPPLY PORTS

TO THE OIL FILTER

Pix 1154

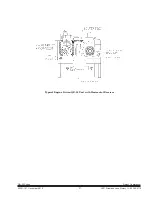

Fig. 5-6 Relocating

Countersunk Pipe Plug

5120_31.TIF

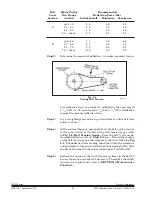

Fig. 5-5

Driveshaft Alignment

CAUTION!

MAKE SURE THE FORKS OF THE BEARING

CARRIER DRIVESHAFT LINE UP PROPERLY

WITH THE PIN IN THE END OF THE CRANK-

SHAFT DURING REASSEMBLY!

Step 2) Rotate the oil pump housing

1

/

2

turn (180°). Note: The rota tional

arrow at the top of the pump housing should now reference

the direction you wish the compressor to rotate. Make sure

the forks of the bearing carrier driveshaft line up properly

with the pin in the end of the crankshaft during reassembly.

(See Fig. 5-4,

Compressor Directional Arrows

and Fig. 5-5,

Driveshaft Alignment.

)

Step 3) Reinstall the six (6) housing bolts and torque them in a star or

cross pattern to specifications outlined in the parts book.

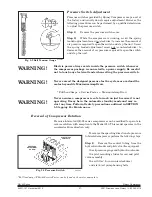

Step 4) Remove the countersunk pipe plug

*

from the oil pump housing and

relocate it in the opposite (bottom) hole. (See Fig. 5-6,

Relocating

Countersunk Pipe Plug

)

Failure to relocate this pipe plug will re sult in complete loss of oil flow

throughout the compressor. Compressor seizure will result and warranty

will be void. The countersunk pipe plug must always be relocated in the

bot tom port position.

Step 5) Install a new oil filter*. Tighten the filter

1

/

2

turn after initial gasket

con tact.

Step 6) Reassemble the control components in reverse order.

Step 7) Double check the directional arrows.

Step 8) For aircooled models only, remove the standard compressor sheave

and replace with a reverse rotation sheave available from your

local Quincy Compressor distributor.

Step 9) Start the compressor and adjust the oil pressure.

Summary of Contents for QR-25 210

Page 42: ......