10

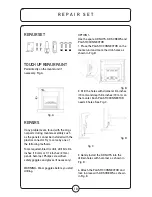

OPTION 1:

Use the spare KD NUTS, KD SCREWS and

PLASTIC CONNECTOR.

1. Place the PLASTIC CONNECTOR on the

mantel unit and mark the drill-holes as

shown in Fig. B.

fig. B

2. Drill the holes with diameter 3/4 inches

(10 mm) and depth 3/4 inches (10 mm) on

the mantel. Each PLASTIC CONNECTOR

needs 3 holes. See Fig. C.

fig. C

fig. D

3. Gently install the KD NUTS into the

drilled-holes with hammer as shown in

Fig. D.

4. Attach the PLASTIC CONNECTOR and

lock in place with KD SCREWS as shown

in Fig. E.

REPAIR SET

TOUCH UP REPAIR PAINT

Paint directly on the mantel unit if

necessary. Fig. A.

fig. A

REPAIRS

If any problems are found with the origi-

nal parts during mantel assembly such

as the panels cannot be installed with the

plastic connector. Try to solve by one of

the following methods.

Tools required: Electric drill, drill bits 3/4

inches (10 mm) or 1/16 inches (2 mm),

pencil, hammer, Philips screwdriver,

safety goggles and gloves (if necessary).

WARNING: Wear goggles before you start

drilling.

R E P A I R S E T

Summary of Contents for M850P-26FDC

Page 13: ...13...