Page 20

7075-205

April 29, 2013

R

Voyageur Grand

Fire Risk

When lining air-cooled factory-built chimneys:.

• Run approved chimney liner

• Re-install original factory built chimney cap

ONLY

• DO NOT block cooling air openings in chimney

• Blocking cooling air will overheat the chimney

WARNING

E. Prefabricated Metal Chimney (Cont’d)

To maintain the functionality of the fireplace’s chimney

system you may use a Simpson Dura-Vent DuraLiner

Slip Hanger, Part # 4671, and attach to the bottom of the

fireplace chimney cap to support the liner. You have two

options to completing the installation.

Option one - Not required to use liner cap

:

Re-attach the existing top of the chimney cap.

Option two - Using liner cap:

Re-attach the existing top of the chimney cap and install

a new storm collar and a new liner cap.

WARNING! Risk of Fire --

Follow venting manufacturer’s

clearances and instructions when installing venting system.

3000

3000

or less

More than 3000

600 min.

3000

increase as necessary

until nothing within

3000mm of flue top

Any nearby structure

increase from 1000mm

minimum until clear within

3000mm of flue top

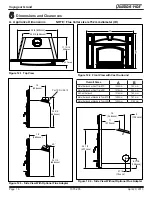

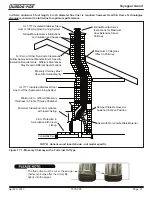

Figure 16.1 Minimum Height of Flue System Exit

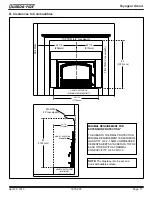

F. Installation Into A Masonry Fireplace

The insert must be installed as per the requirements of

your local inspection authority. It is recommended to use

a full liner as it is the safest installation and provides the

most optimum performance. Your retailer should be able to

help you decide which system would be the best for your

application.

The use of this connection method not only increases

the safety of your insert by directing the hot gases up the

flue, but will also help increase the unit’s efficiency and

decrease creosote deposits in the chimney.

When a connected flue or liner is in use, the insert is able

to “breathe” better by allowing a greater draft to be created.

This great draft can decrease problems such as difficult

start-ups, smoking out the door and dirty glass.

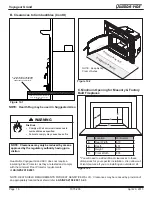

G. Installation Into A Factory Built Fireplace

1. When installed in a factory built fireplace, a full stainless

steel rigid is mandatory, for both safety and performance

purposes. When a flue or liner is in use, the insert is able

to breathe better by allowing a great draft to be created.

The great draft can decrease problems such as difficult

start-ups, smoking out the door, and dirty glass.

2. In order to position the flue liner, the existing rain cap

must be removed from your chimney system. In most

cases the flue damper should also be removed to allow

passage of the liner.

3. In most cases opening the existing spark screens fully

should give enough room for the insert installation. If it

does not, remove and store.

4. If the floor of your fireplace is below the level of the

fireplace opening, adjust the inserts leveling bolts to

accommodate the difference. When additional shimming

is required, use non-combustible masonry or steel shims.

5. Measure approximately the alignment of the flue liner

with the position of the smoke outlet hole on the insert

to check for possible offset. If an offset is required, use

a proper stainless steel unit available with the chimney

liner.

6. Once the above items have been checked, slide your

insert into position after first positioning the flue liner

and offset if required. (Re-install raincap at completion

of installation).