April 29, 2013

7075-205

Page 19

R

Voyageur Grand

6

Chimney Systems

3. Both methods must be removable and replaceable

for cleaning and re-installation.

• When possible, install an airtight clean-out door to the

rear of the smoke shelf.

NOTE:

Masonry chimneys are significantly less than ideal

for venting solid fuel appliances. A masonry chimney is not

subject to any temperature limit test, therefore a full reline is

strongly recommended.

E. Prefabricated Metal Chimney

The chimney can be new or existing, masonry or prefabricated

and must meet the following minimum requirements:

• Must be minimum 152 mm inside diameter of high

temperature chimney.

• Must use components required by the manufacturer for

installation.

• Must maintain clearances required by the manufacturer

for installation.

• Refer to manufacturers instructions for installation

•This insert is listed to UL 1482 Standard and is approved

for installation into listed factory-built solid fuel fireplaces

listed to UL 127 conforming to the following specifications

and instructions:

•The original factory-built clearance fireplace chimney cap

must be re-installed after installing the approved chim

-

ney liner meeting type UL 103 HT requirements (2100°F)

per UL 1777.

•The liner must be securely attached to the insert flue collar

and the chimney top.

•The air flow of the factory-built solid fuel fireplace system

must not be altered. The flue liner top support attach

-

ment must not reduce the air flow for the existing air-

cooled chimney system.

•No dilution air is allowed to enter the chimney.

1.

Secure the fireplace damper in the open position. If

this cannot be accomplished, it will be necessary to

remove the damper.

2. Seal damper area of chimney around chimney

connector with a high temperature sealant or seal

insert against the face of the fireplace.

3. Both methods must be removable and replaceable

for cleaning and re-installation.

NOTE: Refer to chimney liner manufacturer for recom-

mendations on supporting the liner. Installation into

fireplaces without a permit will void the listing.

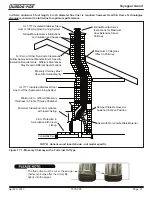

A. Venting Systems

Chimney Connector:

It is also known as flue pipe or stove

pipe. It must be 152 mm minimum diameter stainless steel

connector pipe.

Chimney

: The chimney can be new or existing, masonry

or prefabricated and must meet the following minimum

requirements as specified below.

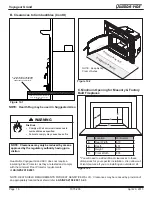

WARNING! Risk of Fire!

Follow venting manufacturer’s clearances and instructions

when installing venting system.

B. Inspections

Existing chimneys should be inspected and cleaned by a

qualified professional prior to installation. The chimney must

not have cracks, loose mortar or other signs of deterioration

and blockage.

C. Larger Chimneys

Hearth & Home recommends that chimneys with larger

diameters than 152 mm be fully relined. An oversized

flue can affect draft and impair performance and will allow

increased build-up of creosote which is why a full reline is

stongly recommended.

D. Masonry Chimney

• Must have at least 16 mm fireclay lining joined with

refractory cement.

NOTE: Installations into a clay flue without a

stainless steel liner may reduce draw which affects

performance, will cause the glass to darken and

produce excessive creosote and create start-up

issues.

•

The masonry wall of the chimney, if brick or modular block,

must be a minimum of 102 mm nominal thickness.

•

A chimney of rubble stone must be at least 305 mm thick.

• Should be lined with a 152 mm stainless steel flue liner

to improve performance and reduce creosote build-up

and difficulty starting a fire.

•

An equivalent liner must be a listed chimney liner system

or other approved material.

• No dilution air is allowed to enter the chimney.

1.

Secure the fireplace damper in the open position. If

this cannot be accomplished, it will be necessary to

remove the damper

2. Seal damper area of chimney around chimney

connector with a high temperature sealant or seal

insert against the face of the fireplace.