26

7080-166B

April 18, 2018

TREKKER

EXHAUST

TEMPERATURE

SERIAL PORT

(SERVICE &

BLUETOOTH CABLE)

FUSE

M

M

M

110 V

LINE

NEUTRAL

IGNITER

FEED MOTOR

EXHAUST

BLOWER

CONVECTION

BLOWER

VACUUM

SWITCH

SNAP

DISC

BLACK

WHITE

PURPLE

PURPLE

BLUE

BLUE

ORANGE

WHITE

BLACK

BLACK

SNAP

DISC

HOPPER

SWITCH

ENCODER (SPEED SENSOR)

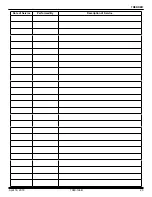

Figure 26.1 - Control Board Schematic

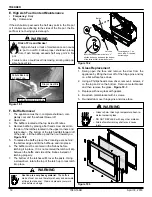

burn back into the feed system, the drop tube snap disc will

shut the appliance down. If there is not enough circulation

from the convection blower the second snap disc will shut

the feed system off. Either sensor must be manually re-set

if tripped. Disconnect power before resetting.

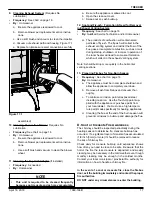

12. Exhaust Probe - Exhaust Blower

The exhaust probe is a temperature-sensing device attached

to the exhaust blower housing via screw and clamp. It pro

-

vides sympathetic exhaust temperature feedback to the control

board. In turn, the control board uses this information to adjust

its heat-output systems for best performance.

13. Vacuum Switch

The vacuum switch is located on the right side of the appliance

under the feed motor, behind right side panel. Its vacuum hose

connects to the drop tube. This switch turns the feed system

on when vacuum is present in the firebox. The vacuum switch

is a safety device to shut off the feed motor if the exhaust or

the heat exchanger system is dirty, plugged, or if the firebox

door is open.

14. Wiring Schematic for Control Board (below)

When describing the location of a component, it is

always AS YOU FACE THE FRONT OF THE APPLIANCE.

A. Component Functions

1.

Exhaust Blower

The combustion (exhaust) blower is mounted in the bottom right

rear of appliance. The blower is designed to pull the exhaust

from the appliance and push it out through the venting system.

2.

Control Board

The control board is located on the right side of appliance. It

controls the functioning of the appliance and communicates

with the user interface through the Bluetooth key. The control

board can only be replaced by an authorized dealer.

3.

Convection Blower

The convection blower is mounted at the bottom left of the

appliance. The convection blower pushes heated air through

the heat exchange system into the room.

4.

Feed System

The feed system is located on the right side of the appliance

and can be removed as an entire assembly. The hollow feed

spring (auger) pulls pellets up the feed tube from the hopper

area and drops them down the feed chute into the fire pot.

Reference the parts list for individual parts in feed assembly .

5.

Fire pot

The fire pot is made of high quality ductile iron. The floor of

the fire pot opens for cleaning and is manually operated by the

homeowner. The floor needs to return to a completely closed

position or the appliance will not operate properly.

6.

Fuse

The control board fuse will blow should a short occur. The con

-

trol board will need to be replaced. DO NOT REPLACE THE

FUSE. If the control board fuse blows its TRIAC, that portion

of the circuit, will remain closed causing the motor on that leg

to run

continuously

at high speed.

7.

Heat Exchanger

The heat exchanger is located behind the baffle and transfers

heat from the exhaust system into the convection air chamber.

Remove the cast iron baffle to access the heat exchanger.

8.

Hopper Lid Switch

The hopper lid switch is located on the right side, inside the

hopper. It switches the feed motor off if the hopper lid is open.

9.

Igniter (Heating Element)

The igniter is mounted on the base of the fire pot. Combustion

air travels over the red hot igniter creating super heated air that

ignites the pellets.

10.

Power Receptacle

The power receptacle is located below the control box on

right side. Install the power cord (supplied in the appli-

ance component pack) to the appliance receptacle. Prior

to installing, check the wall receptacle for 120 volt, 60 Hz

(standard current). Make sure the outlet is grounded and has

the correct polarity. A good quality surge protector is highly

recommended to protect the appliance electronics.

11. Overheat Snap Discs

T

here are two overheat snap discs located within the elec-

tro-mechanical cavity of the appliance. One is mounted on the

back of the drop tube in the center of the appliance; the other

is mounted in the RH side between the firebox and cast side

panel. Both snap discs have a reset button. If the fire tries to

E

5

Reference Materials