24

7037-171E

August

13,

2018

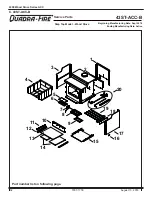

4300 Wood Stove Series ACC

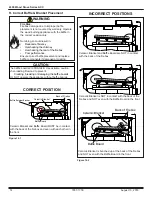

Figure 24.1

Channel

Access

Cover

Channel

Nuts (2)

Side Panel

Tube Channel

Assembly

Channel Cover

Screws (4)

Tube Channel Rack

Remove

2 Screws

Slide one gasket

over each tube

F. Tube Channel Assembly Replacement

Removing Tube Channel Assembly

1. Remove the right side shield by removing 2 screws in

the back using a Phillips head screw driver.

2. Remove 4 screws from channel access cover and

remove cover.

3. Locate 2 channel nuts inside of chamber and remove

using a 7/16 socket wrench. Slide out tube channel

assembly.

NOTE

: Soak the bolts with penetrating oil for at least 15

minutes before trying to remove them.

Replacing Tube Channel Assembly

1.

Slide one gasket onto each tube.

2.

Slide the tube channel assembly into side of firebox

and insert each tube into the corresponding hole in the

tube channel rack starting with the back hole first.

3.

Make sure tube channel assembly is flush against the

side of the appliance and secure with channel nuts.

4. Re-install channel cover and side shield.

NOTE: Service Space

In order to replace the tube channel assembly a

clearance of 19 inches (483mm) is required on the right

side of appliance in order to remove the tubes with the

appliance in place.

If space is not available, the appliance will have to be

disconnected from the chimney to proceed with the tube

replacement.