16

7033-361B

November,

2021

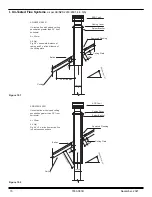

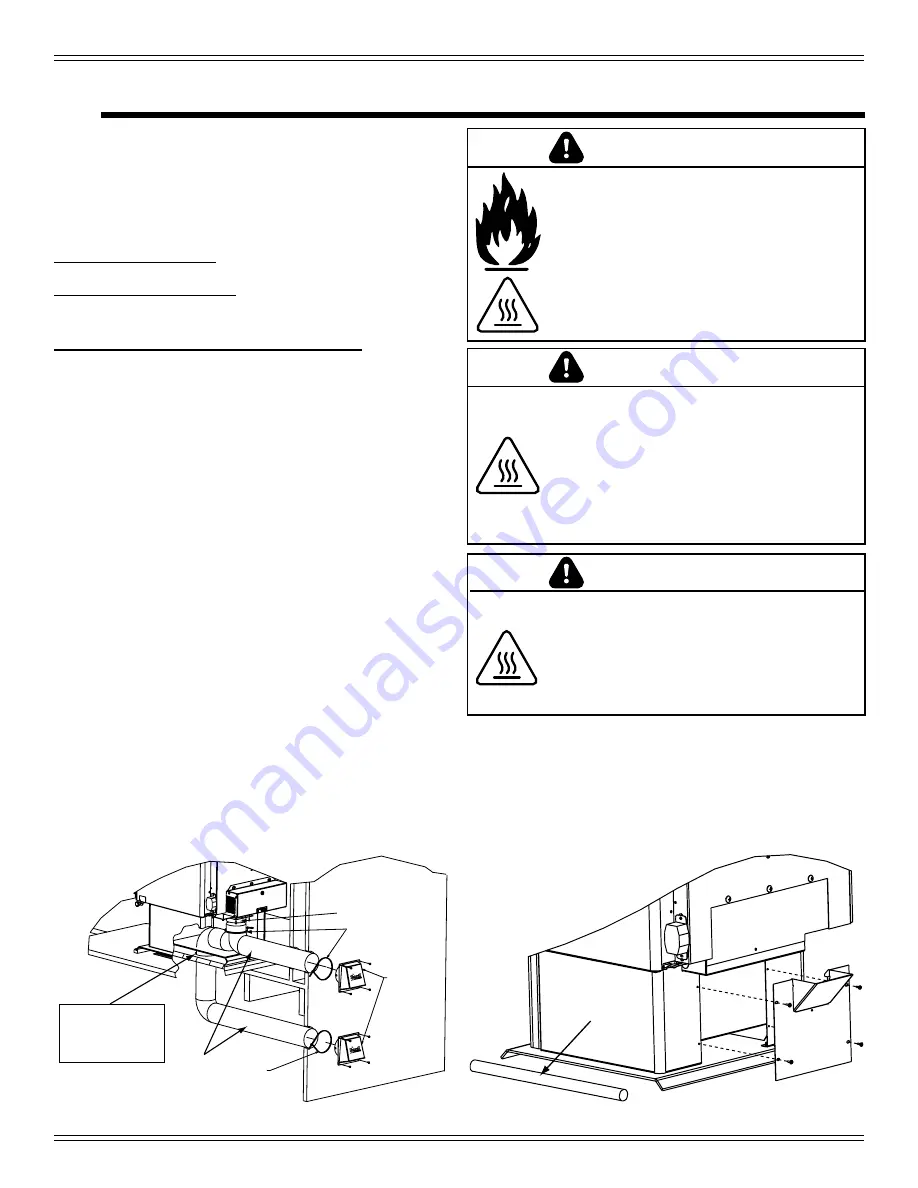

Flex Line

Wire Tie

Wire Tie

Flex Adapter

Termination

Cap

For Floor Installa-

tions Remove

Circular “Knock-Out”

in Base of Pedestal.

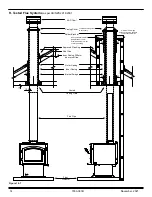

Figure 16.2

Cover

Plate

Rope to Seal

Pedestal

Items Needed for Installation (not supplied)

-

102mm flex aluminum pipe, or if using alternate

material, then it shall be made from durable,

non-combustible, heat resistant material up to

350oF. Cut the pipe to the required length for your

installation.

- Phillips head screw driver

- Silicone sealant

- Drills and saws necessary for cutting holes through

the wall or flooring in your home.

1. Remove all materials from packing box.

2.

Using a #2 Phillips screw driver attach the flex adapter

to the appliance using 4 screws

(Figure 16.1)

3.

For floor installations, remove circular” knock-out” in

the base of the pedestal.

4. Floor & Rear Installation:

Cut a 102mm hole in

outside wall or floor to accommodate outside air piping.

Use 102mm aluminum metal flex or rigid piping to

directly connect outside air to appliance intake. Use

the supplied termination cap with a rodent screen. Seal

between the wall (or floor) and the pipe with silicone to

prevent moisture penetration.

5. Floor Installation Alternative:

In some instances

you may not be able to install the flex pipe as show in

Figure 16.1

. If that is the case, you will need to order

SRV7033-041 which includes a cover plate and sealing

rope as shown in

Figure 16.2

. The goal is to seal the

pedestal so no room air can leak into the pedestal or

for cold air infiltration.

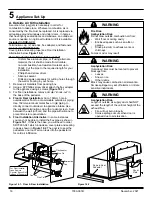

A. Outside Air Kit Installation

A source of air (oxygen) is necessary in order for

combustion to take place. Whatever combustion air is

consumed by the fire must be replaced. Air is replaced via

air leakage around windows and under doors. In homes

that have tightly sealed doors and windows, an outside air

source is needed. An optional Outside Air Kit is available.

Included in OAK-ACC:

Termination cap, (2) wire ties, flex adapter, and fasteners

Included in SRV7033-041:

Cover plate and sealing rope (see Floor Installation

Alternative below,

Figure 16.2

)

Figure 16.1 - Floor & Rear Installation

5

Appliance Set-Up

WARNING

Asphyxiation Risk.

Outside air inlet must be located to prevent

blockage from:

• Leaves

• Snow or ice

• Other debris

Block may cause combustion air starvation.

Smoke spillage may set off alarms or irritate

sensitive individuals.

WARNING

Fire Risk.

Asphyxiation Risk.

Do not draw outside combustion air from:

•

Wall, floor or ceiling cavity

• Enclosed space such as an attic or

garage

• Close proximity to exhaust vents or

chimneys

Fumes or odor may result

Asphyxiation Risk.

Length of outside air supply duct shall NOT

exceed the length of the vertical height of the

exhaust flue.

• Fire will not burn properly

• Smoke spillage occurs when door is

opened due to air starvation

WARNING

Summary of Contents for 31M-ACC-AU

Page 19: ...19 7033 361B November 2021...