Quad Power Brush

Operators Manual – Version 06

3

WHEN IN USE:

Attach the clip end of the Tether Cord

to your belt, until you dismount the ATV. The switch the

cord is attached to: will shut off the engine if pulled

deliberately or by inadvertently dismounting from the

ATV seat.

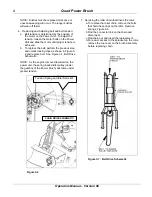

Gage Wheels

1. The gage wheels (one on each side) are to be used

on surfaces that are not hard enough for the full

weight of the brush, such as sweeping leaves on

grass. The wheels are not needed for hard

surfaces, such as concrete or asphalt.

2.

When not used:

the gage wheel assemblies can be

removed from the unit OR stored upside down in

the same holder and tightened (refer to procedure

3).

3. Lift the Brush and adjust the wheels to the desired

height, depending on the degree of aggressive

desired. Secure the gage wheels with the offset

locking pins (Figure 3-5) to achieve proper locking

tightness.

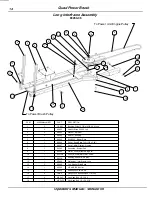

Figure 3-5

GENERAL OPERATION

1. Start brush engine and warm up at LOW RPM.

2. Increase engine RPM to desired speed and

start operating. Refer to the Power Unit Manual

for illustrations and operation of throttle

controls).

3. Operate brush so wind blows debris away from

operator, engine and power unit.

4. For a longer lasting brush; take note of the

following:

a) More pressure does not produce a better sweep

b) A level brush lasts longer.

c) The faster the ground speed, the faster the

brush will wear.

d) More aggressive brush down pressure will

reduce brush life.

5. Drive at low speed.

6. When climbing curbs or loading brush on trailer,

raise brush to maximum height and drive slowly.

The bristles might come in contact with curb or

trailer ramp.

STORAGE

1. Keep all nuts, bolts and screws properly tightened.

This maintains the unit in good working condition.

2. Remove weight from brush bristles by putting

blocks under the frame and setting up gage wheels

to maintain brush to floor clearance.

3. Refer to Power Unit manual on storage instruction

for the Power Unit

MAINTENANCE

1. Refer to the engine manual for servicing and

lubrication specifications and intervals.

2. Clean engine air cleaner frequently (hourly, if

necessary, if subject to a lot dust).

3. Clean debris from engine and gearbox area after

each use.

4. The gearbox is sealed and therefore the oil level

cannot and is not required to be checked.

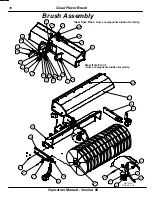

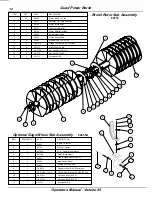

5. Bristles wear off after time and will be in need of

replacement:

a.

Disconnect the roller chain that attaches the

gearbox to sprocket on the brush.

b.

Remove the bolted front shield for easier access,

if desired, but not necessary.

c.

Remove the bearing (Figure 3-5) on each side of

the brush and slide out the shaft.

d.

Remove bolts from bristle shaft and replace all

bristles at once.

NOTE:

Refer to pages 10 to 13 of the Parts

Replacement Section of this manual.