17 Operating Your Cleaner

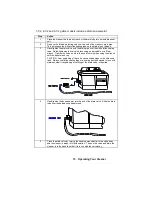

Over temperature protection (C-only)

- the cleaner will shut down at

75ºC and the LED display will blink “75”. Turn the cleaner off and allow it

to cool down. For a faster cooldown, replace some of the warm solution

with cold solution.

Solution

Solution activity

- the amount of visible activity is not necessarily related

to optimum cavitation for cleaning.

Degassing

- fresh solutions contain many dissolved gases (usually air),

which reduce effective ultrasonic action. Although solutions will naturally

degas over time, using Degas mode speeds up the degassing process.

Solutions that have been sitting unused for 24 hours or longer have

reabsorbed some gases.

Heat

- increases the chemical activity of cleaning solutions.

Surface tension

- can be reduced by adding solution to the bath.

Reduced surface tension will increase cavitation intensity and enhance

cleaning.

Solvents

- never use solvents. Vapors of flammable solutions will collect

under the cleaner, where ignition is possible from electrical components.

Renewal

- replace cleaning solutions often to increase ultrasonic

cleaning activity. Solutions, as with most chemicals, will become

depleted over time. Solutions can become contaminated with suspended

soil particles which coat the tank bottom, inhibiting ultrasonic activity.