16 Operating Your Cleaner

Optimizing Your Cleaner

Tanks

Cleaning

- check the tank for contamination whenever you change

solution. If necessary, remove contaminants with a nonabrasive cloth

and water.

Emptying

- always unplug the cleaner before emptying the tank. Empty

the solution into a waste disposal unit.

Filling

- always unplug the line cord before filling the tank. Fill the

cleaner to the operating level (one inch from the top with beaker/tray in

place), using warm tap water.

Low solution level

- will cause the cleaner to fail. When you remove

heavy or bulky loads from the cleaner, the solution level may drop below

the operating level. If so, be sure to replace lost solution and degas, if

necessary, depending on the amount used.

Overload

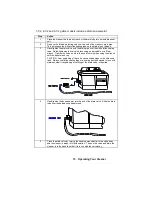

- do not rest any items on the tank bottom. Weight on the tank

bottom dampens sound energy and will cause damage to the transducer.

Instead, use a tray and/or beaker positioning cover to support all items.

Allow at least one inch between the tank bottom and the beaker or

receptacle for adequate cavitation.

Covers

- allow the cleaner to heat up faster, to a higher temperature, and

avoid excessive liquid evaporation. However, obstructing the cover vents

will cause the cleaner to overheat.

Temperature

Heater

- the heater may cause some discoloration of the tank wall. This

is normal and will not affect the performance of the unit.

Solution

- the fastest method to heat your cleaner is to fill with warm

solution, use heat, ultrasonics (which also adds heat), and a cover.

Approximate stabilization temperatures with ultrasonics and heat running

continuously:

CHT/C cleaner without a cover 50º

CHT/C cleaner with a cover 62º

continued...