6

•

ALWAYS

ensure fire extinguishing

equipment is readily available and

properly maintained.

ALWAYS INSPECT SPRAYING AREA

•

Keep the spraying area free from

obstructions.

•

Make sure the spraying area has good

ventilation to safely remove vapors

and mists.

•

NEVER

keep flammable material in

spraying area.

•

NEVER

spray in vicinity of open flame or

other sources of ignition.

•

The spraying area must be at least 20

ft. away from spray unit.

TOXIC FLUID HAZARD

•

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in eyes or on skin, inhaled or swallowed.

Know the hazards of the fluid you are

using. Store & dispose of hazardous

fluid according to manufacturer, local,

state & national guidelines.

•

ALWAYS

wear protective eyewear,

gloves, clothing and respirator as

recommended by fluid manufacturer.

HOSES

Do not allow kinking or crushing of hoses or

allow it to vibrate against rough, sharp or

hot surfaces.

•

NEVER

use a damaged hose. Before

each use, check entire hose for cuts,

leaks, abrasions, or bulging. If any of

these conditions exist, replace the hose

immediately.

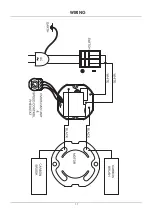

GROUNDING

•

G r o u n d t h e s p r a y e r & o t h e r

components in the system to reduce

the risk of static sparking, fire or

explosion which can result in serious

bodily injury and property damage. For

detailed instructions on how to ground,

check your local electrical code.

•

ALWAYS

ensure switch is in OFF position

before plugging unit in.

Always Ground All of These Components:

1. Turbine:

plug the power supply cord,

or extension cord, each equipped

with an undamaged three-prong

plug, into a properly grounded outlet.

DO NOT USE AN ADAPTER.

Use only

a 3 wire extension cord that has a

grounding plug, and a receptacle

that will accept the grounding plug on

the product. Make sure your extension

cord is in good condition. When using

an extension cord, be sure to use one

heavy enough to carry the current your

product will draw. If in doubt, use the