5

Assembly and installation manual

QIM/QDB Mixer Series

QIM/QDB-M01

Before servicing pump, disconnect

electrical power source, carefully relieve

all pressure and drain all fluids from

pump and connected piping.

DESCRIPTION

Before servicing pump, disconnect electrical power source.

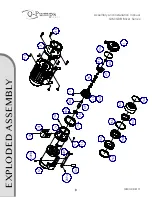

The

QIM/QDB Mixer Series

closed-coupled pumps are made up of two sections, power or drive

section and the liquid end or pump section.

The pump is mounted to the frame of the drive motor by means of an adapter, and is coupled

to the motor shaft. The impeller mounts on the stub shaft and is retained by one of the three

methods. The casing is clamped to the adapter, greatly simplifying removal, and also permitting

positioning of the discharge outlet through 360º. The external, balanced seal assures long seal

life. The drive motor is mounted on a frame having adjustable legs providing simple installation

and leveling.

INSTALLATION GUIDELINES

UNPACKING EQUIPMENT

Check the contents and all wrapping when unpacking your equipment. Inspect all parts for

damage that may have occurred during shipping. Report any damage to the carrier.

LOCATION AND INSTALLATION

The pump unit should be located as near as possible to the liquid source and in a position where

the suction piping can be short and direct with a minimum number of elbows and fittings. It

should also be readily accessible for inspection and cleaning.

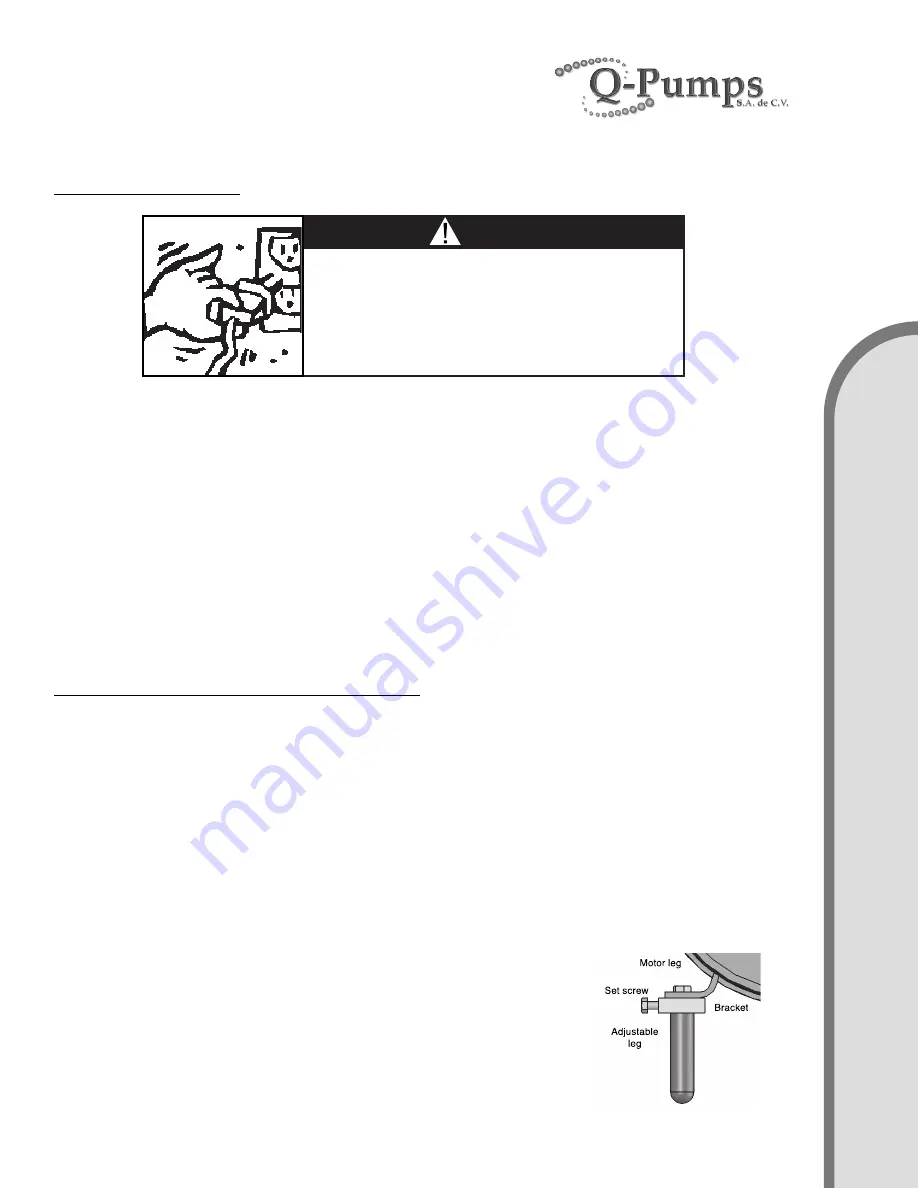

The pump unit as received from the factory is ready for installation. To install it, attach a hoist if

necessary, loosen the set screws in the adjusting leg brackets, and individually adjust the legs

until the pump is leveled. Tighten the set screws.

Attach the suction and discharge piping. Be sure suction and

discharge piping is properly supported to avoid any strain on the

pump casing.

WARNING

SAFET

Y