Model: PWD Rev. B_12/2/2015

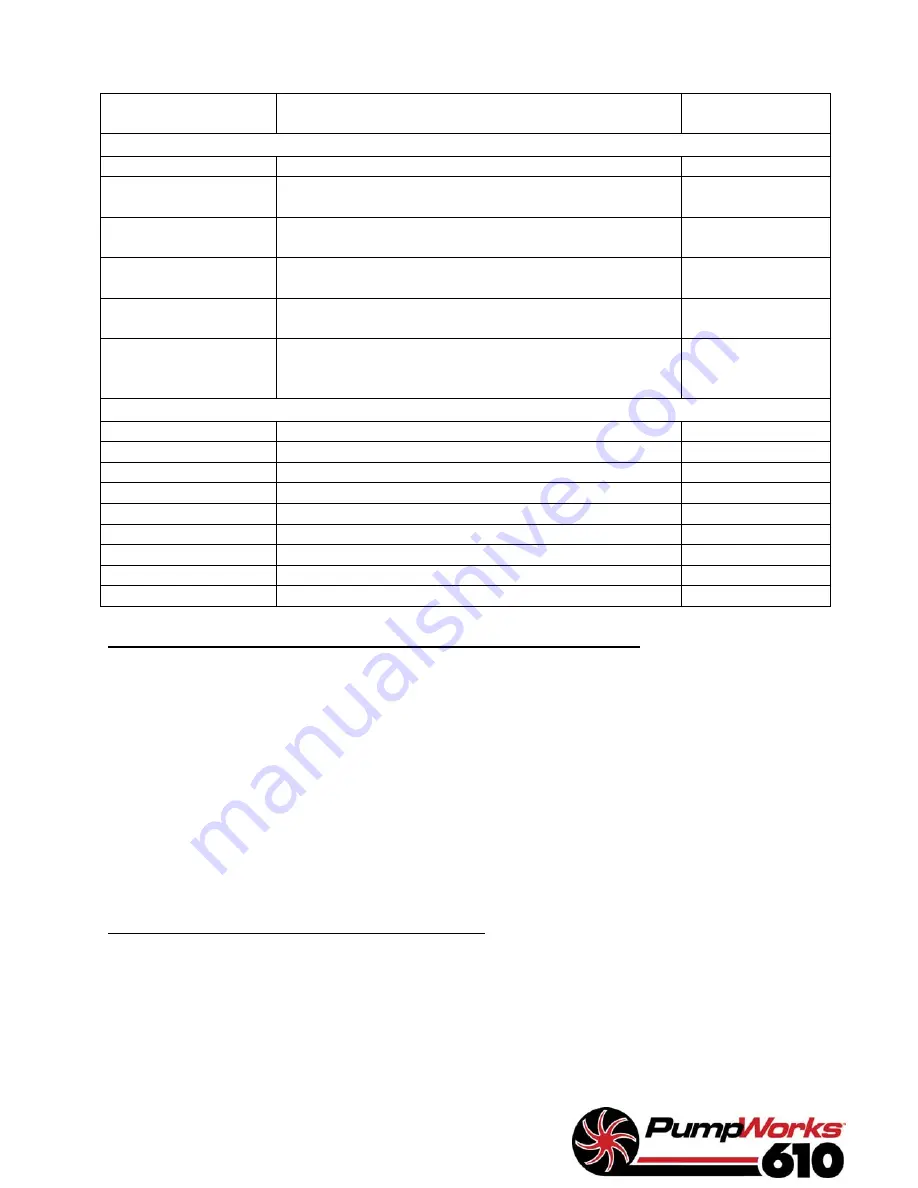

Preventative

Maintenance

Description Frequency

Initial Startup & Commissioning

Oil System

Change Lube Oil

1

st

250 hours

Suction Strainer

Check pressure differential across suction strainer

Every 2 Hours for

1

st

Day

Mechanical Seal

Visually inspect

1

st

Hour After

Startup

Auxiliary Piping

Visually inspect

1

st

Hour After

Startup

Instrumentation

Check instruments for proper function and verify

calibration readings.

1

st

Hour After

Startup

Unit Monitoring

Monitor bearing temperature rise and stabilization. Ensure

no sudden temperature rises. Check vibration readings for

abnormalities.

1

st

8 Hours After

Startup

Normal Operations

Oil System

Change Lube Oil (Continuous Operation)

Every 2000 hours

Oil System

Change Lube Oil (Standby Operation)

Every 6 Months

Lube Oil Filters

Check pressure differential across filter.

Daily

Suction Strainer

Check pressure differential across suction strainer

Daily

Unit Monitoring

Monitor vibration, bearing and case temperatures

Daily

Mechanical Seal

Monitor for leaks

Daily

Auxiliary Piping

Visually inspect

Monthly

Cleanliness

Check for oil leakage and dust buildup

Monthly

Performance

Check pump performance & efficiency

Every 6 Months

Table 1

MECHANICAL SEAL / BEARING HOUSING REMOVAL

Packages manufactured by PumpWorks610

are made for replacement of the mechanical

seals, without disturbing the pump or driver. For

this purpose, packages are supplied by

PumpWorks610, and in compliance with API

610 specifications, with a spacer coupling to

allow clearance for seal removal

The following procedures are given as a

customer reference only, and do not necessarily

cover every step of removal for every

configuration of construction. It is the end users

responsibility to ensure that care is taken not to

damage components, fits, and finishes which

could cause leakage of the product, possible

failure of bearings, or of the entire unit.

Maintenance should be performed by

experienced and qualified personnel, and should

be performed in compliance with all safety

regulations and procedures.

PumpWorks610 maintenance personnel are

available for service, supervision, training, or

consultation.

Anytime bearing housing is

disturbed replace ball bearings.

Removal

instructions are as follows:

BALL / BALL BEARING HOUSING (INBOARD)

1) Follow all Lockout/Tag Out Procedures prior

to removal of guards and maintenance of

unit.

Ensure

ALL

electrical sources have

be de-energized and locked out.

Ensure suction, discharge, and

bypass valves have been closed

and secured.

Drain fluids from pump and bearing

housing that is to be removed. Use

proper precautions for hazardous or

flammable liquids. Remove constant

oiler globes. Refer to applicable

MSDS sheets as necessary.

2) Remove

coupling

guard.

3) Remove RTD probes, as applicable.