Version 1.0

Version 1.0

Troubleshooting

48

48

Trolley

Electric Trolley

Manual Trolley

Condition

Reason

Action

Cause

Correction

No drive due to wheel skid

Rail tilt

Confirm rail slope is within 1 °

Improper rail settings

Set up orbit correctly

No drive due to wheel skid

Apply oil above orbit

wheel tread.

Ensure wheel is clean and

unobstructed

Use in environment which

outside material does not

interfere with parts

Clean orbit regularly

Audible friction when travelling

on curve track

Friction resistance

between wheel and

rail

Apply lubricating oil on track tread

No drive on curve track

Interference of curve

track and trolley

Confirm that orbit curve’s radius is

minimal bending radius

Curve track exceeding limit

value

Avoid use on curve track

exceeding limit value

Wheel raised and unable to be

driven

Inclined pull (wheel

raised)

Operation method

Correct use

Wheels stopped revolving

Faulty gear connec

-

tion

Ensure clean space between wheel

and gear

Interference from outside

material

Check regularly

Abnormal sound

Improper adjustment

circle

Confirm adjustment circle number

and insert position

Insufficient confirmation

Install correctly

Wear of wheel

Confirm wear degrees

Traveling surface has bump

Confirm regularly

Deformation of

wheel

Check wheel bending and surface

damage

Excessive collision, traveling

surface deformed

Replace and use correctly

Aging of wheel

bearings

Confirm irregular sound exists

when wheel rotates

Reaching service life

Replace

Deformation and

wear of track

Confirm rail wear and deformation Overload or reaching service

life

Replace and use correctly

Condition

Reason

Action

Cause

Correction

Wheels stopped revolving

Brake gelling

Open motor cover remove rust and

dirt

Usage environment

Inspect regularly

Electric fault

Refer to items of electric chain hoist

Abnormal sound

Wear of edge guide

wheel

Confirm wear degrees

Reaching service life

Confirm regularly

Wear of friction

slices

Confirm wear degrees of friction

slices

Reaching service life

Confirm regularly

Condition

Reason

Action

Cause

Correction

Unable to move hand chain

Bad connection

between hand wheel

and hand chain

Properly adjust hand chain on hand

wheel

Excessive or improper usage Replace worn or deformed

components

V.07.22 [LA]

Summary of Contents for PWJTHF

Page 2: ...This page intentionally left blank...

Page 19: ...Version 1 0 19 Specifications 19 V 07 22 LA...

Page 20: ...Version 1 0 Specifications 20 20 V 07 22 LA...

Page 33: ...Version 1 0 33 Parts 33 1 4 Trolley assembly drawing V 07 22 LA...

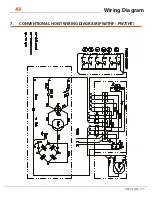

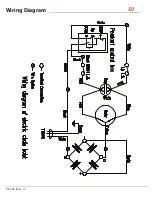

Page 49: ...49 Wiring Diagram 49 7 CONVENTIONAL HOIST WIRING DIAGRAM PWJTHF PWJTHT V 07 22 LA...