Version 1.0

45

Troubleshooting

45

Electric shock

Hook

Condition

Reason

Action

Cause

Correction

Electric shock upon touching

machinery or control switch

Equipment not prop

-

erly grounded

Measure earth resistance. If below

100Ω assemble ground wire

Improper ground wire con

-

nection

Firmly connect ground wire

Ground wire bad connection Assemble carefully to prevent

loose screw

Cable break

Do not apply excessive force on

cable

Dampness/ water

Clean, use once dry

Wet hands

Do not operate with wet hands

Condition

Reason

Action

Cause

Correction

Hook mouth open

Hook deformation

Replace hook if deformation is

beyond permitted range.

Overload

Operate under rated voltage

Lifting (hook connected with

grounded object)

Do not lift grounded objects.

Load hanging on hook head;

hook pull horizontal

Lifting load properly with hook

Hanger suspension errors Lifting angle must be controlled

within 120 °

Load size exceeds rated hook

Using proper hook

Hook twist

Chain wrapped around load

Do not wrap chain

Head hook improper rotating

Bearing rust, corro

-

sion

Hand rotation; maintain or replace

if experiencing difficulty rotating

Inadequate grease

lubricant; corrosion

Apply grease lubricant regularly;

prevent hook contamination of

chemical agents

Bearing damage

Dust

Prevent foreign matter from

entering head

V.07.22 [LA]

Summary of Contents for PWJTHF

Page 2: ...This page intentionally left blank...

Page 19: ...Version 1 0 19 Specifications 19 V 07 22 LA...

Page 20: ...Version 1 0 Specifications 20 20 V 07 22 LA...

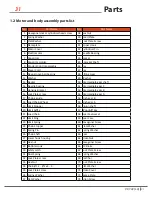

Page 33: ...Version 1 0 33 Parts 33 1 4 Trolley assembly drawing V 07 22 LA...

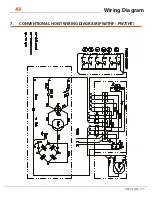

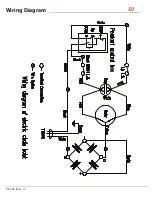

Page 49: ...49 Wiring Diagram 49 7 CONVENTIONAL HOIST WIRING DIAGRAM PWJTHF PWJTHT V 07 22 LA...