operaTIon

EmpyrE ElItE Xt InstallatIOn and OpEratIOn manual

19

Take the following precautions to protect the fire brick and

maintain optimal performance.

1. Do not carelessly throw heavy pieces of wood onto the

brick.

2. Gently rake ashes out of secondary burn chamber.

3. Do not damage brick while stirring the fire.

4. Do not attempt to cool down hot bricks quickly.

5. Do not run furnace with pieces of brick missing.

6. Do not alter the brick and insulation layout. This layout

has been carefully engineered to achieve the best

performance.

Blower draft setting

The blower and flapper unit flap opening settings are pre-

determined by the factory and must NOT be altered. Altering

these components could cause damage to the furnace and

void the warranty. To replace any of these components you

must contact your Empyre Elite XT dealer.

nOtE:

This is not a natural draft furnace. It is a forced air

furnace where the blower controls the fire.

doors

The Empyre Elite XT doors have an adjustable hinge and

latch. Adjust doors to maintain a tight gasket seal. Keep

doors closed and maintain all door seals in good condition.

Exhaust Exit lever Operation

When the exhaust exit lever above the loading door is in the

right hand position, the furnace is in its normal operating

mode. When the lever is moved to the left, the furnace is

now in the loading mode. In the loading mode the exhaust

exit is open at the rear top of the firebox and air is directed in

front of the baffle. The blower will only run for a timed period

and then shut off. To reactivate the timer, the lever must

be moved to the full right position and then back to the left

position, or switch furnace off and back to on.

loading procedures:

1. Move lever to the left hand side and wait momentarily.

Slowly open the loading door.

2. Rake the ash and load the firebox. Note: if blower shuts

down before loading is complete, reactivate by moving

the lever fully to the right and then back to the left.

3. Close door securely and move lever fully to the right.

Note: if the lever is not fully to the right the furnace

WILL NOT operate.

to maintain optimal performance:

1. Do not leave loading door open for extended periods of

time, especially when the fire is very hot.

2. Do not force the loading door open beyond the stop.

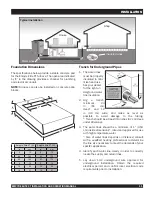

power Outages

The Empyre Elite XT furnace, unlike a gas or oil fired

appliance, does not stop generating heat when the power

is interrupted even though the blower automatically shuts

off causing the fire to die down. As a result the heat transfer

fluid in the furnace may overheat and boil off through the

vent. When power resumes be sure to check the fluid level.

Operation do’s and don’ts

1. When loading wood keep the loading door open for the

least amount of time as possible.

2. After loading wood, when wood is burning hot DO NOT

open the loading and ash doors for several hours. This

will avoid hot discharge from the doors and keep chimney

temperatures at a proper operating level.

3. When wood is burning hot DO NOT unneccesarily shut

off the furnace and then turn it back on. Wait at least 10

minutes before turning it back on. This will avoid back

pressure coughing through the chimney when the furnace

comes back on.

4. DO NOT open ash door when the wood is burning hot or

just after the furnace shuts off. If not sure, open loading

door first before ash door. This will avoid hot discharge

from the open door.

5. DO NOT fill the firebox with very dry wood. Extremely dry

wood will burn excessively fast which will cause smoke,

back pressure and coughing through the chimney.

6. Reloading when the wood is burnt down to only ashes

(the same applies for starting a new fire): start fire with

paper and small pieces of wood, then continue adding

bigger pieces. After 10 minutes, reposition the wood.

In some instances you may need to reposition the wood

several times. Important: DO NOT have door open or lever

to the left more than necessary. If there is only smoke and

the air from the open door ignites the fire, the slots are

plugged and the wood needs to be repositioned to ensure

air is flowing into the secondary burn chamber.

When the brick has cooled, it will take extra effort to get a

good fire going as the wood will bridge more.

7. Always keep some hot wood coals on the brick. As

needed, level off the bed of coals with the rake before

reloading.

Summary of Contents for Empyre Elite XT

Page 1: ...Installation and Operation Instructions Empyre Elite XT Model 100 and 200...

Page 2: ......

Page 31: ......