operaTIon

18

EmpyrE ElItE Xt InstallatIOn and OpEratIOn manual

4. For the most efficient burn always keep the brick

hot by maintaining wood in the firebox.

5. DO NOT cover the brick slots when placing wood

into the firebox.

daily routine

morning loading:

Load wood into the unit as described above.

late afternoon Check:

Check the unit to ensure there is sufficient wood to burn

until the end of the day. Load just enough fuel to ensure

a bed of burning charcoal is in the firebox prior to the

night loading.

Note: The firebox is hottest when the wood has burnt

down to a bed of charcoal. When the primary chamber

has burnt down to this level, the firebox will dry out

and burn most of the accumulated creosote on the

walls. If the primary chamber is full all of the time, the

temperature in the firebox stays quite cool and creosote

may build up on the walls.

night loading:

Rake the coal and ash from the perimeter of the firebox

and especially from the back wall of the chamber where

ash tends to build up. With the ask rake, pull the ash

and charcoal away from the walls. The force of the fan

will blow the ash into the lower chamber on its own. If

this is done every day the ash should fall through the

slots easily.

Load wood into the unit as described above.

Cleaning Out ash

Firebox and secondary Burn Chamber

Ash in the secondary burn chamber should be cleaned

out weekly or as necessary, depending on fuel quality

and burn rate. Clean ash out of the secondary burn

chamber first. Then clean the firebox. Otherwise hot

wood coals will be scraped out of the secondary burn

chamber along with the ash.

To clean ash out of the firebox, gently rake it into the

secondary burn chamber through the opening in the

bottom of the firebox. It is important to rake ash buildup

away from the back wall of the firebox.

1. Do this when the fire has died down before reloading

furnace. Switch blower off.

2. Open ash clean out door.

3. Pull out ash tray.

4. Reach the ash rake to the back of the chamber and

pull ash forward into the ash tray. Do not scrape all

of the ash into the ash tray. It is recommended to

leave 1”-2” (2.5 - 5.1 cm) of ash covering the floor of

the firebox.

5. Firmly close and latch ash clean out door.

6. Switch blower on.

Flues and Chimney

Switch furnace off.

For highest efficiency clean the heat exchanger flues

weekly or as necessary.

1. Clean ash from secondary burn chamber before

cleaning flues.

2. Remove flue clean out cover (see page 9).

3. Push brush completely through flues. Should the

brush be too difficult to push through, then first push

the rod through and pull from the other end.

4. Inspect and clean any buildup in the exhaust area.

5. Install clean out covers and secure rear access door

latch with bolt and tighten with wrench.

6. Open ash clean out door and ensure the ash is

cleared from the flues.

Switch furnace on.

disposal of ash

Ashes should be placed in a metal container with a tight

fitting lid. The closed container of ashes should be placed

on a noncombustible floor or on the ground, well away

from all combustible materials, pending final disposal. If

the ashes are disposed of by burial in soil or otherwise

locally dispersed, they should be retained in the closed

container until all cinders have thoroughly cooled.

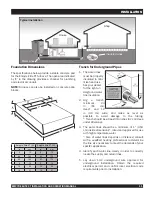

Creosote - Formation and need for removal

When wood is burned slowly, it produces tar and other

organic vapors, which combine with expelled moisture

to form creosote. The creosote vapours condense on

the relatively cool firebox walls of a slow burning fire. As

a result, creosote residue accumulates on the firebox

walls. When ignited this creosote makes an extremely

hot fire. To reduce the amount of creosote, a small

intense fire is preferrable to a large smoldering one.

Fire Brick and Insulation

The secondary burn chamber of the Empyre Elite XT high

efficiency furnace is lined with high temperature insulation.

It is designed to sustain high furnace temperatures and

regular operation for many years. The floor of the firebox is

lined with brick. To see signs of wear and cracking of the

brick is normal.

Summary of Contents for Empyre Elite XT

Page 1: ...Installation and Operation Instructions Empyre Elite XT Model 100 and 200...

Page 2: ......

Page 31: ......