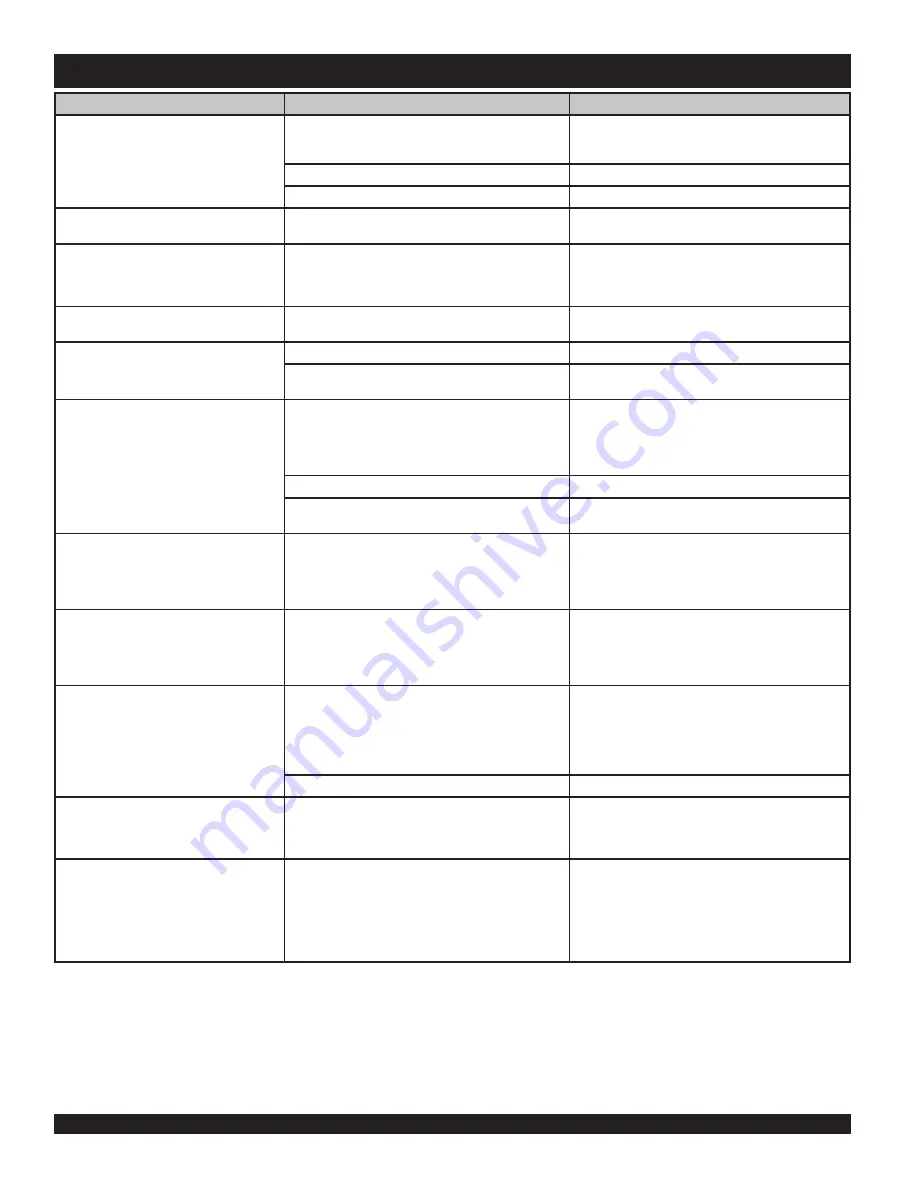

TroubleshooTIng

28

EmpyrE ElItE Xt InstallatIOn and OpEratIOn manual

prOBlEm

pOssIBlE CausE

sOlutIOn

Blower will not come on.

High limit switches may be shut off because

the water temperature is higher than aqua-

stat setting permits.

Wait for the water to cool down. Reset snap

disc, see page 9.

No electricity.

Check power supply.

Blower overheated.

Wait for blower to cool down.

Blower is on but no air in firebox.

Flapper unit flap stuck shut.

For information on a sticking flapper see

page 24.

The water overheated and boiled over.

After refilling the water, temperature is

below operating range, but there is no

power coming through to the blower.

The high limit switch (snap disc) has tripped

the circuit.

The high limit switch (snap disc) has a

manual reset. Press button to reset. To

locate snap disc see page 9.

There is some smoke coming from

the chimney most of the time.

Wood is too dry or bridged.

Burn only seasoned wood. Reposition wood.

Furnace overheats and boils.

Main door has been left open.

Close door.

Main door and/or ash clean out gaskets are

leaking.

Replace gaskets or adjust latches and/or

hinges.

Low heat output.

Wood moisture is too high causing the wood

to bridge. Note: when bridging happens there

is an air space between the wood and the

firebox floor. The air then exits the firebox

without causing the wood to burn.

Use seasoned wood. Cut wetter pieces 8

inches (20 cm) shorter than the firebox and

load the logs centered in the firebox. Split

the bigger logs. Place the logs carefully so

they will not bridge.

Fire has almost died out before refuelling.

Add wood before the fire has burned down.

Wood is hung up and bridged because of

incorrect length and loading.

Place logs centered over the brick slots/air

passage on the firebox floor.

Low heat output.

The brick slots/air passage in the firebox

floor is blocked by charcoal/ash.

Using the ash rake, always stir the firebox

charcoal/ash into the lower ash chamber

before adding wood. Limit the charcoal/

ash buildup and let the charcoal burn down

before adding wood.

It is difficult to get a fire started.

Brick slots on the floor of the firebox are

blocked.

Place small pieces of wood so air can flow

through. Avoid flat pieces of wood that could

block the air when laid flat on the firebox

floor. As you add more wood place the wood

so air can flow through.

Fire dies out with wood still left in

the firebox.

The furnace has been on the off cycle for too

long causing the wood to bridge or hang up.

Flapper is stuck shut from the furnace idling

too much.

In spring/fall when one load of wood lasts

more than 16 hours do not fill up the firebox.

To further avoid bridging, stack the wood so

the lowest part of the stack is in the centre.

In spring/fall use only 6 inch (15 cm) diam-

eter and smaller seasoned logs.

Not drawing enough heat from the furnace.

Increase the heat draw on the furnace.

Furnace water temperature is over

180°F (82°C) but no heat in the

building.

Circulating pump is off due to one or more of

the following: a bad connection, temperature

is set too low, valves are closed, air is in the

system or the water level is low.

Check for loose connections; open valves if

closed; bleed air out of system; add water if

level is too low.

Smoke coming from open loading

door.

Cause could be one or more of the follow-

ing: opening door too quickly, opening door

soon after loading wood, furnace blower is

off, loose wires, faulty switch/timer, too small

or too short a chimney, negative pressure in

furnace room.

Open slowly waiting 30 seconds after mov-

ing lever to the left; do not open when fire

is hot; switch blower on; move lever left

and right, blower should be on in the load

position; check limit switches/timer and

wire connections; install longer and bigger

chimney; increase venting to furnace room.

Summary of Contents for Empyre Elite XT

Page 1: ...Installation and Operation Instructions Empyre Elite XT Model 100 and 200...

Page 2: ......

Page 31: ......