Your Air X is delivered partially assembled. Assembly requires mounting

the blades on the blade hub, securing the hub to the turbine body and

installing the nosecone on the blade hub. The necessary hex key (Allen)

wrenches are furnished with Air X.

Torque Specifications:

Blade to hub bolts, 1/4-20 x 1.25 inch, Socket Head Bolt, 7.0 lb-ft (9.4 N·m)

Hub to rotor nut, 5/8 -18 inch, Jam nut, 50 lb-ft (68 N·m)

Yaw Clamp Bolts, M5 x 35 mm, Socket Head Bolt, 4.0 lb-ft (5.4 N·m)

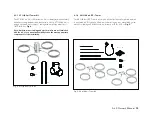

Start the assembly by examining how the blades mount to the hub, refer to

Fig 1

. Using the Tef-Gel supplied with the Air X, apply a coat of Tef-Gel to

the blade root and hub. The use of Tef-Gel is recommended for all installa-

tions but is mandatory in marine environments.

The goal is to provide a coating of Tef-Gel between the blade root and

blade hub so that the blade material does not directly contact the alumi-

num hub. This is particularly important for marine installations since the

blades and hub may severely deteriorate in high moisture (particularly

marine) environments.

After coating the hub and blades with Tef-Gel place a nylock nut (Item 4)

in the detent on the back of the blade hub while positioning a blade on

the hub. Pass a bolt through the blade and screw it into the nylock nut –

do not fully tighten the bolt yet. Install the second bolt and nylock nut and

torque both bolts to

If Air X is to be installed on a “tilt-up” tower, mount the blade/hub assem-

bly to the turbine now. Start the 5/8-18 hub nut on shaft threads and

“spin” the hub completely onto the turbine

alternator shaft. Fully tighten the hub to

50 ft-lbs (68 Nm) by inserting a 5/16 inch

hex key wrench in the turbine alternator

shaft and turning the shaft while turning

the blades.

Caution

- blades are sharp!

If Air X is to be installed after the tower is erected, it will be safer and

easier to first install the turbine body on the tower and then install the

hub/blade assembly. This will avoid attempting to mount the turbine while

the blades are spinning – a dangerous condition.

Snap the nosecone into position over the outside edges of the blade hub.

Make sure all three edges of the nosecone snap over the edge of the

blade hub. After installation tug on the nosecone to make sure it is secure-

ly attached.

Two - Air X Turbine Assembly

IMPORTANT:

Tef-Gel is a corrosion inhibitor and

is especially important in marine applications.

WARNING:

Don’t

attempt to mount the

turbine while blades

are spinning.

Air X Owner’s Manual

Fig. 1 Air X Blade Attachment Detail.

1- Air X Blade Hub

2- Air X Blade

3- 1/4 - 20 Socket Head Cap Screw (2)

4- 1/4 - Nylock Nut (2)

5- Apply Tef-gel here

lightly

temporarily hold the blade in place. Install the

.

remaining two blades following the same procedure. Measure tip to tip to

tip distance between the three blades and align as needed to measure as

equal a distance apart as possible. Torque all blade bolts to 7 ft-lbs. (9.4 Nm).

10

5

3

1

4

2