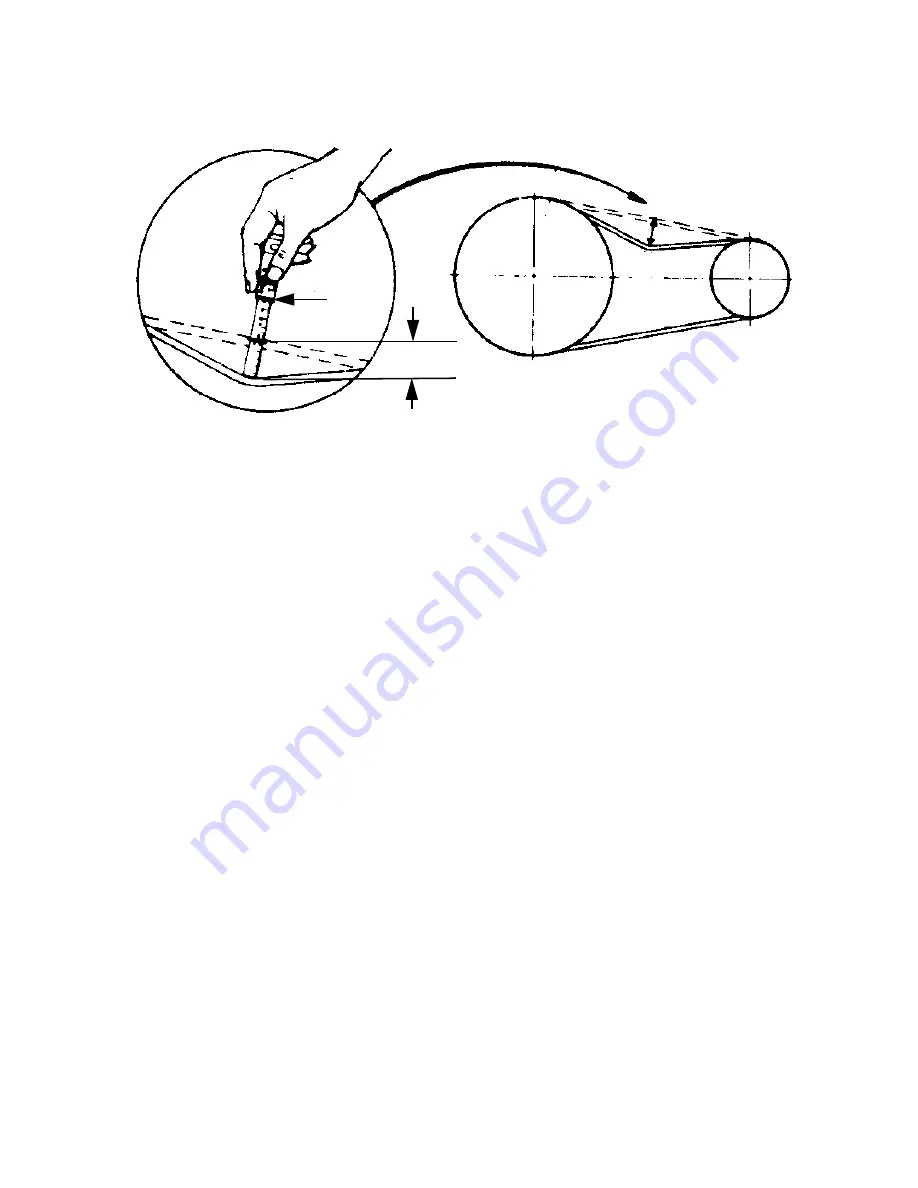

Diagram 5.4 - Measuring Belt Tension

15. If the locking tabs on the right and left step up belt tension bolts have not been straightened,

use pliers to bend the locking tabs out of the way so that the bolts can be turned.

IF...

THEN...

The belt tensioning gauge reads

Turn both tension bolts

less than 14 pounds

clockwise

, in equal quarter-turn

increments, until the belt tensioning

gauge reads 14 - 16 pounds @1/4” deflection.

The belt tensioning gauge reads

Turn both tension bolts

more than 16 pounds

counterclockwise

, in equal

quarter-turn increments, until the belt

tensioning gauge reads 14 - 16 pounds @ 1/4”

deflection.

16. Verify that the belt alignment is still correct by performing the procedure in step 4.

17. When both the step pulley belt tension and alignment are correct, use pliers to bend the

tension bolt locking tabs into the “locking” position.

18. The input pulley tension must now be checked and corrected, if necessary. There is not

sufficient room to use the belt tension gauge to set the input pulley belt tension. It will be

necessary to use the correctly tensioned step up belt as a comparison to set the input belt

tension.

19. Using your finger, press in on the center of the step up pulley belt to get a feeling of how

much pressure it takes to deflect the belt a 1/4”.

20. Using your finger, press in on the center of the lower span of the input belt. Compare the

pressure required to deflect the input belt to the pressure required to deflect the step up belt.

15 lbs

1/4”

Summary of Contents for EFX EFX 5.23

Page 79: ...Block Diagram 8 2 5 23 5 25...