5

ELECTRICAL SAFETY

To reduce the risk of fire, connect only to a circuit

provided with a 7A / 10A maximum branch circuit

overcurrent protection in accordance with BS1362.

Do not work alone under hazardous conditions.

Check that the power cord(s), plug(s), and sockets

are in good condition.

To reduce the risk of electric shock, disconnect

the equipment from the AC power outlet before

installing or connecting to other equipment.

Reconnect after all electrical connections are made.

Use one hand, whenever possible, to connect or

disconnect signal cables to avoid a possible shock

from touching two surfaces with different

electrical grounds.

Connect the equipment to a three wire AC connection

(live, neutral and ground). The unit must be connected

to appropriate branch circuit/mains protection

(fuse or circuit breaker). Connection to any other

type of connection may result in a shock hazard.

In order to maintain compliance with the EMC

directive, wires attached to the Powervault

should not exceed 25 meters in length.

• Prepare the electrical wiring according to figure 1 or figure 2. All wiring to be perform in strict accordance with

local building regulations.

• The ideal installation will feature a separate RCBO block splitting from the Henley Block as shown in figure 1.

• If this is not possible connecting to consumer unit is acceptable as long as it is on a dedicated 16A RCBO can be

inserted into the unit as shown in figure 2.

• The rotary isolator will need to be installed directly downstream of the dedicated RCBO.

• If a power socket needs to be added for the Powervault internet connection then the additional power socket

should be installed downstream of the rotary isolator as shown in figure 1.

• The fused spur should be rated according to table 1.

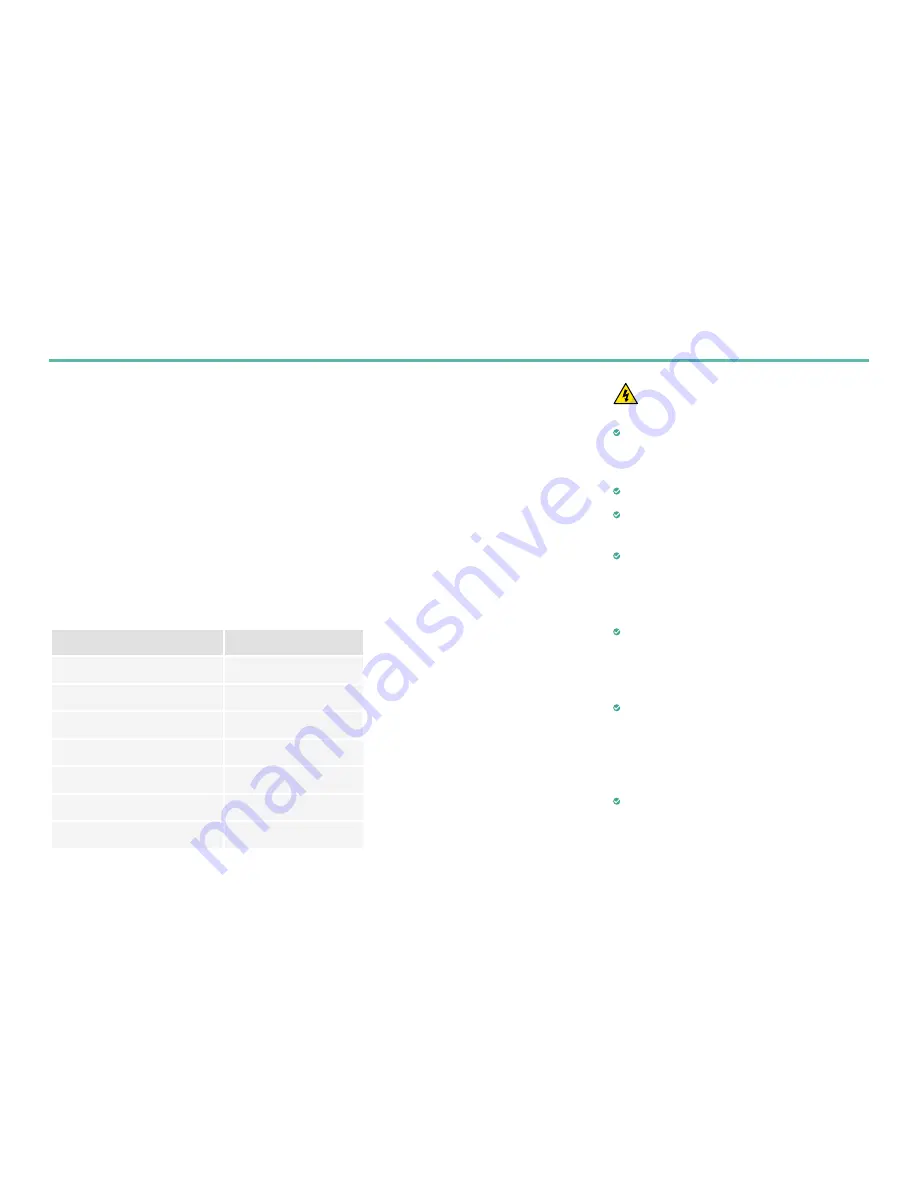

TABLE 1

Unit

Fused Spur Rating (amps)

3kWh Lead Acid (AGM Gel)

7

4kWh Lead Acid (AGM Gel)

7

2.5kWh Lead Acid (Tubular Gel)

10

4.0kWh Lead Acid (Tubular Gel)

10

2kWh Lithium-ion

10

4kWh Lithium-ion

10

6kWh Lithium-ion

10

Part 1: Wiring