PowerQuick Powered Ascender

(23)

PQ500-1 1-Sep-15

ensure that the machine/equipment is stopped, isolated from all potentially hazardous energy sources, and locked out before

any service or maintenance where the unexpected energization or start-up could cause injury.

14.3.

Corrosive Environments

The PowerQuick Powered Ascender should not be used in any environment, or with any substance that will cause the equipment

to suffer undue or

excessive

corrosion, or damage the integrity of the equipment.

14.4.

Ropes and Rigging

The PowerQuick Powered Ascender system is based on a twin rope concept with independent primary (working) ropes and

secondary (safety, backup) ropes.

6. Each rope (working and safety) shall be attached to two independent anchorages, via two independent sets of

attachment hardware. If an anchorage is unquestionably adequate, or engineer designed and tested for such

purpose, both sets of attachment hardware might be connected to the one anchorage.

7. The safety rope shall be attached to separate anchorages to the main rope, unless the anchorages are

unquestionably adequate or engineer designed and tested for such purpose. Separate attachment hardware shall

be used for both ropes.

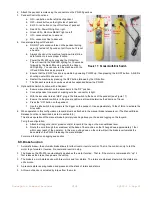

8. Static or Low Stretch kernmantle Ropes shall normally be used for ascending and descending with the PowerQuick

Powered Ascender. Static or Low Stretch Ropes shall be of a kernmantle construction compliant with Cordage

Institute 1801 Low Stretch and Static Kernmantle Life Safety Rope, and have a minimum breaking strength sufficient

to supply the users’ desired calculated system safety factor. In no case shall the safety factor for a rope access

system be less than 5:1. An example of calculating system safety factors is as follows: a 68 kg (150-pound) worker,

to achieve a 5:1 safety factor, must work on a system where the weakest link of the system is calculated to be

capable of sustaining at least 340 kg (750 pounds).

9. Ropes made from nylon or polyester will normally be the most suitable for rope access work. Ropes of other man-

made materials might, however, be required for specific situations. In such cases, great caution should be exercised

in verifying their suitability for the work. Ropes made from high modulus polyethylene, high tenacity polypropylene

and “Kevlar” are types of ropes, which may be considered in exceptional circumstances such as where there is

severe chemical pollution or where the self-weight of the ropes could be a problem. However, H.M. polyethylene

and H.T. polypropylene have much lower melting temperatures than nylon or polyester and may be affected by

frictional heat from capstan. Dangerous softening of polypropylene occurs at temperatures as low as 27 degrees C

(80 degrees F). Kevlar has a very high melting point but poor resistance to abrasion, UV light (including sunlight)

and repeated bending.

PowerQuick Concepts, Inc. will not warrant use of the PowerQuick Powered

Ascender with these ropes

.

10. All ropes and equipment should be individually identified and checked on a daily basis by a competent person.

11. All ropes shall be protected from fraying or wear. When they come into contact with sharp edges or rough surfaces,

sleeves, radius protection or other means of protection should be used.

12. Ropes shall not show any significant signs of abrasion or other damage.

13. The kern must never show through the outside mantel or sheath.

14. Slings and seat boards shall meet appropriate standards and shall have minimum ultimate breaking strengths of

24kN. Note: Inadequate rigging can create unacceptable and dangerous loadings in PowerQuick Powered Ascender

equipment. Correct training and experience is essential.

14.4.1.

Harnesses and Lanyards

The harnesses used with the PowerQuick Powered Ascender shall be a one-piece full-body harness or a sit harness used in

conjunction with a chest harness that is firmly attached to the sit harness.

All body harnesses and lanyards manufactured on or before January 1, 1998, shall be designed and built to conform to ANSI

A10.14 requirements, Requirements for Safety Belts, Harnesses, Lanyards, Lifelines and Drop Lines for Construction and

Industrial Use, which is hereby incorporated by reference.

14.4.2.

Fall Protection

The PowerQuick Powered Ascender must always be used with approved fall arrest equipment.

1. All personal fall arrest, personal fall restraint and positioning device systems manufactured after January 1,

1998, shall be designed and built to conform to either ANSI A10.14-1991 American National Standard for

Construction and Demolition Use, or ANSI Z359.1-1992 American National Standard Safety Requirements

for Personal Fall Arrest Systems, Subsystems and Components, which are hereby incorporated by

reference.

Summary of Contents for PQ 500-1

Page 46: ......

Page 48: ...NOTES...