8

Assembly

Tools required for assembly:

Rubber mallet

17mm open-end ,or socket, wrench

Set of hex (Allen) wrenches

Exposed metal surfaces on the drill press have

been factory-coated with a protectant. Remove

this with a soft rag moistened with a light

solvent. Do not use an abrasive pad and do not

use gasoline, paint thinner or acetone, as these

will damage plastic components and painted

surfaces.

The drill press should be placed in a dry area

with a level floor and good lighting. Provide

enough space around the drill press to allow for

operations and any adjustments or servicing.

Assembly is a two person

operation to avoid injury from accidental

dropping.

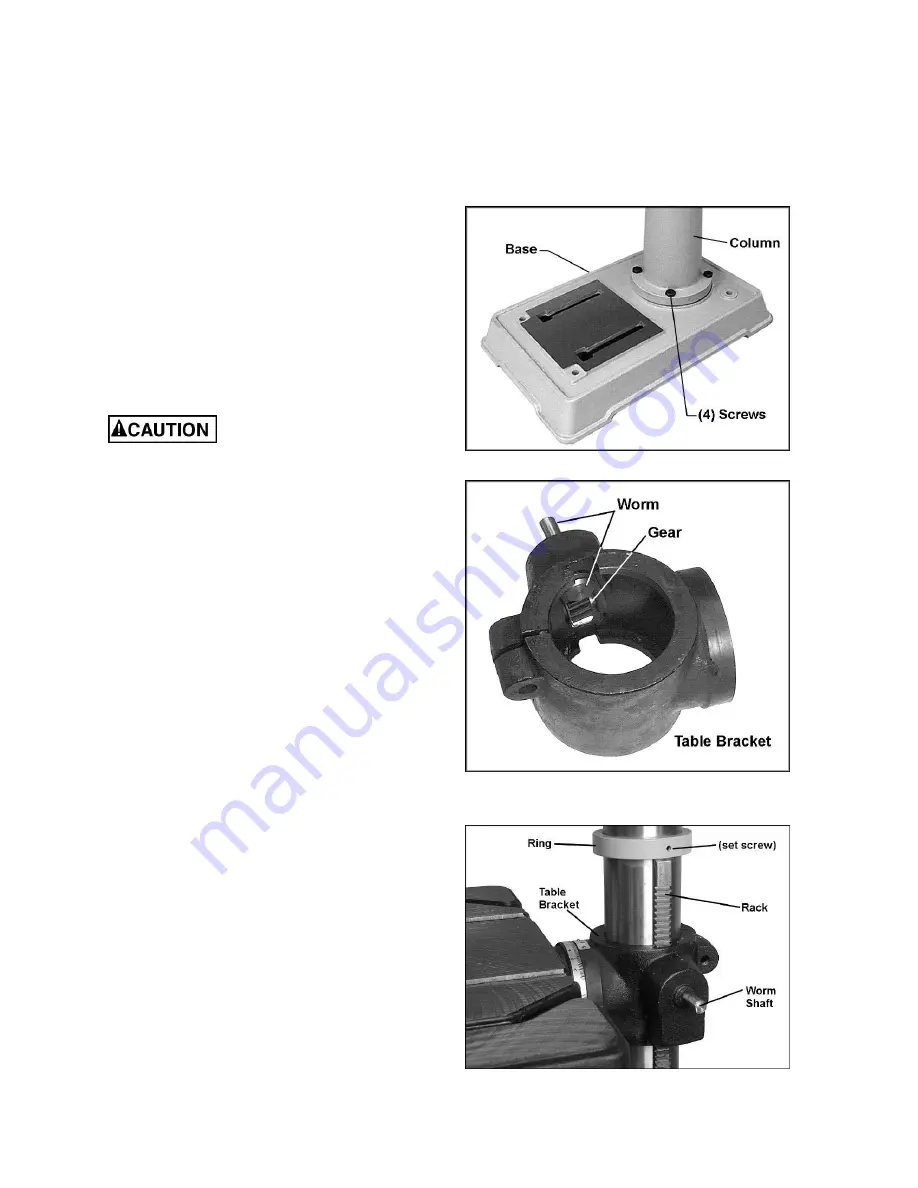

Column

Referring to Figure 2:

1. Place the base (Figure 2) upon a level floor.

It may be secured to the floor with lag

screws (not provided) through the four holes

in the base.

2. If you do not wish to permanently secure the

drill press to the floor, it can be bolted to a

plywood panel which will serve as its base

and further stabilize it. Use a high grade of

plywood at least 3/4" thick. It should be

large enough to prevent vibration, sliding or

moving of the drill press during operation.

Do not use a mobile base with this machine.

3. Attach the column assembly to the base

with four M10x40 hex cap screws, and

tighten with a 17mm wrench.

Table Bracket

When shipped, the ring and rack are bundled

together with the column in plastic wrap.

Referring to Figures 3 through 6:

1. Remove the wrap and take the ring from the

column by loosening the set screw and

sliding the ring off. Also remove the rack.

See Figure 4.

2. Position the worm through the hole in the

table bracket (Figure 3) and push it as far as

it will go until the shaft protrudes and the

worm is meshed with the gear, as shown.

Figure 2

Figure 3

(table shown removed)

Figure 4

Summary of Contents for 2800

Page 20: ...20 Model 2800 Drill Press ...

Page 25: ...25 Electrical Connections ...

Page 26: ...26 Electrical Connections ...

Page 27: ...27 ...