18

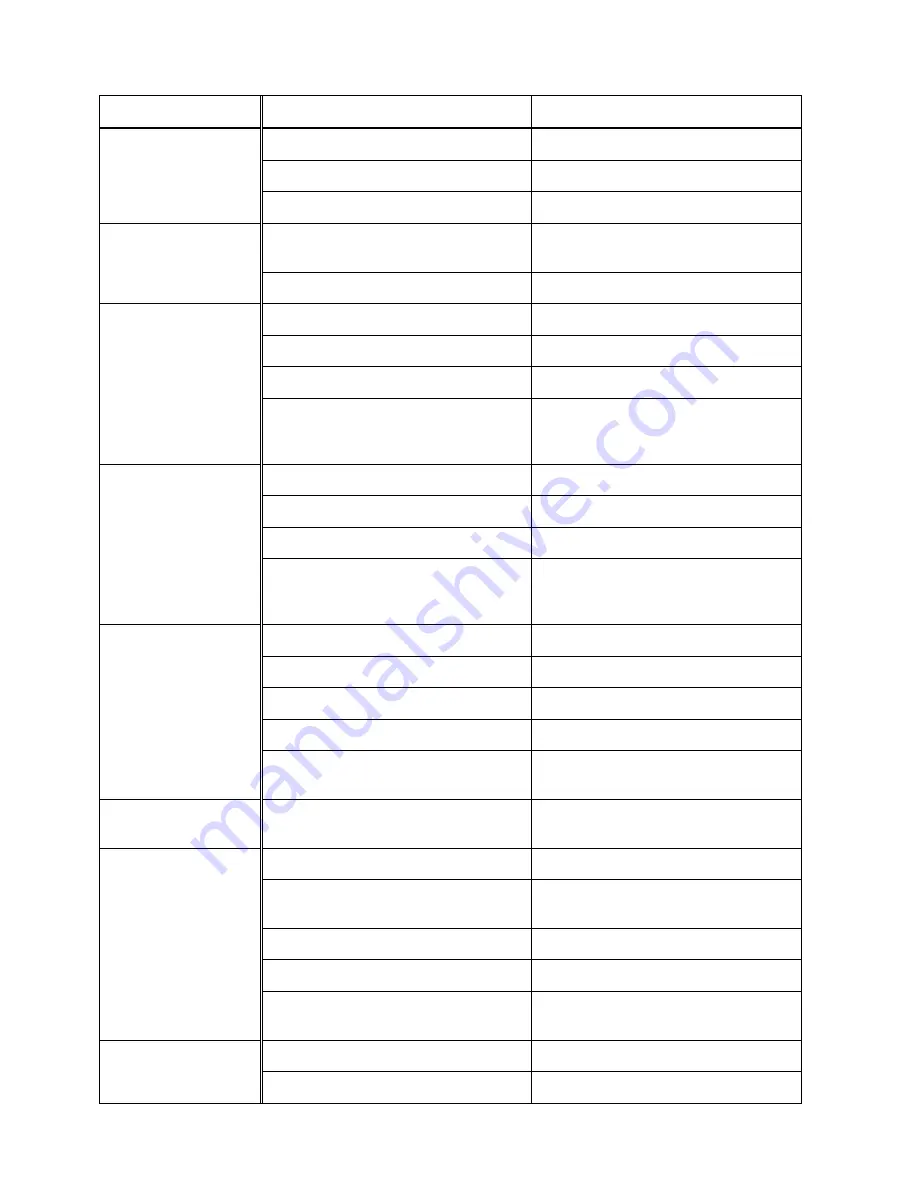

Troubleshooting

Trouble Probable

Cause

Remedy

Drill press will not

start.

Not connected to power.

Check all plug connections.

Fuse blown, or circuit breaker tripped. Replace fuse, or reset circuit breaker.

Cord damaged.

Replace cord.

Drill press does not

come up to speed.

Extension cord too light or too long.

Replace with adequate size and

length cord.

Low current.

Contact a qualified electrician.

Excessive vibration.

Improper belt tension.

Adjust belt tension.

Uneven belt wear (hard spots).

Replace belt.

Motor or spindle pulley out of balance. Balance or repair problem pulley.

Motor malfunction.

Have motor tested by a qualified

service center. Repair or replace as

necessary.

Motor stalls.

Overfeeding the bit.

Reduce feed rate.

Dull bit.

Sharpen or replace bit.

Motor not reaching running speed.

Repair or replace motor.

Motor is malfunctioning.

Have motor tested by a qualified

service center. Repair or replace as

necessary.

;Noisy Operation.

Noisy Operation

(cont.)

Excessive vibration.

See “Excessive Vibration” above.

Incorrect belt tension.

Adjust belt tension.

Dry spindle.

Lubricate spindle.

Loose pulleys.

Make any needed corrections.

Noisy motor.

Check motor bearings or for loose

motor fan.

Wood splinters on the

underside.

No backing board used.

Place a scrap board beneath the

workpiece to prevent splintering.

Drill or tool heats up

or burns workpiece.

Excessive speed.

Reduce speed.

Chips not clearing from hole or bit.

Retract drill bit frequently to remove

chips.

Dull drill bit.

Resharpen, or replace drill bit.

Feeding the bit too slowly.

Increase feed rate.

Rotation of bit incorrect.

Reverse motor rotation (refer to

diagrams on pages 25 and 26).

Drill bit wanders.

Bit sharpened incorrectly.

Resharpen bit correctly.

Bent drill bit.

Replace bit.

Summary of Contents for 2800

Page 20: ...20 Model 2800 Drill Press ...

Page 25: ...25 Electrical Connections ...

Page 26: ...26 Electrical Connections ...

Page 27: ...27 ...