16

4. Connect power to the drill press, and turn on

the laser using the button at the front of the

drill press head.

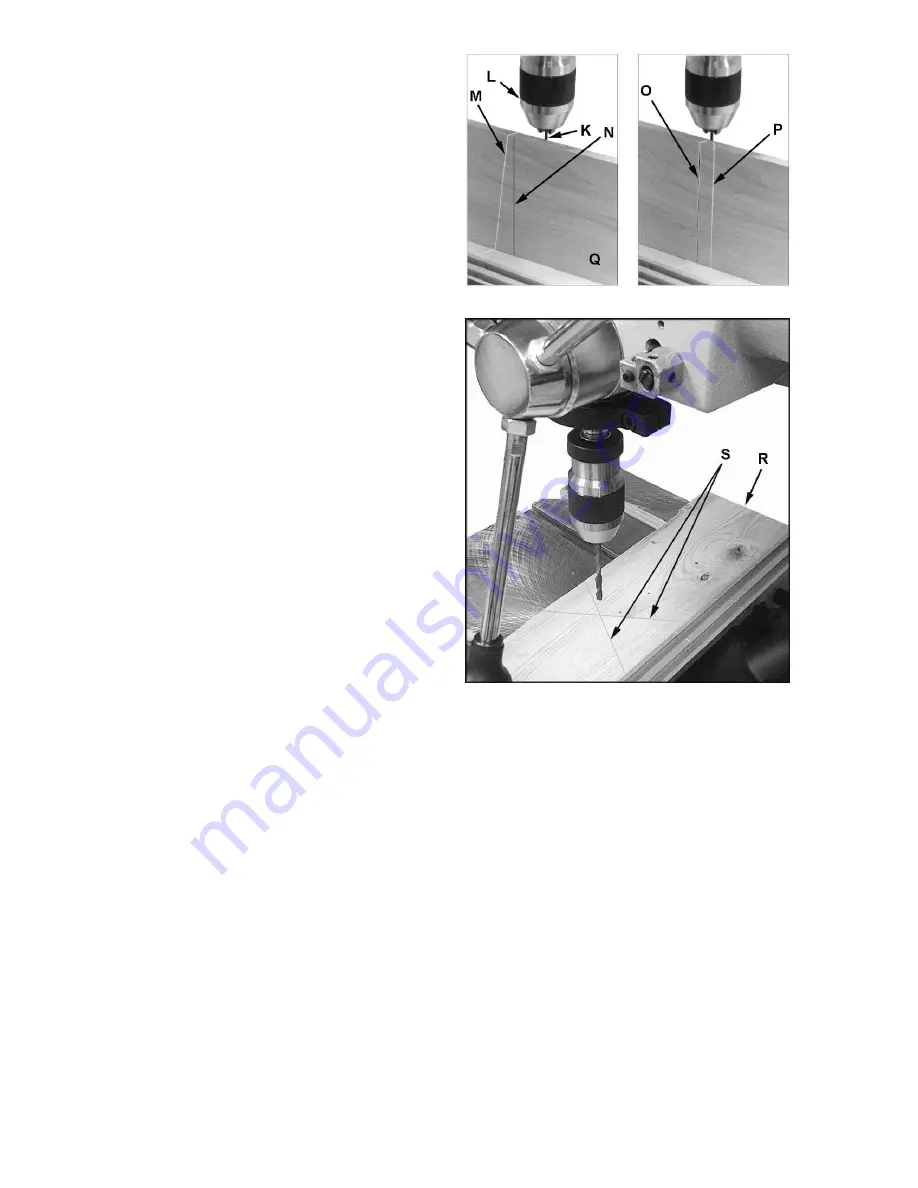

Vertical Alignment

5. Manually rotate the laser assembly (A

2

) and

move the board from side to side as

required until the laser light (M) lines up with

the board marking (N) to look like (O). Then

carefully tighten the three setscrews (E).

Repeat step 5, if necessary, until the light

and marking are aligned.

6.

Adjust the other laser in the same manner.

Two parallel laser markings should look like

O and P in Figure 24 – the distance

between the lines will vary with board

thickness; however, the lines must be

parallel.

Cross Hair Alignment

7. Place

board

(R) flat on the table. Do not

allow the board to move from this position;

use clamps if needed. Bring the bit down

until it

leaves a slight perforation

in the

board; then raise it back up.

8. Loosen one laser

setscrew

(F, Fig. 23) and

adjust (G, Fig. 23) so the laser line crosses

the perforation (S). Tighten setscrew (F).

9. Adjust the other laser assembly in the same

manner

until the laser lines form cross

hairs

(S) exactly over the perforation in the

board.

10. Tighten setscrew (F, Fig, 23). Re-check the

vertical alignment to insure that the laser

lines did not shift during the tightening

process.

The laser is now calibrated properly and the

location of your holes can be centered at the

cross hairs for accurate drilling.

11. Assemble

guards

with pan head screws

over the laser on each side.

Figure 24 (repeated)

Figure 25

Summary of Contents for 2800

Page 20: ...20 Model 2800 Drill Press ...

Page 25: ...25 Electrical Connections ...

Page 26: ...26 Electrical Connections ...

Page 27: ...27 ...