Medical Air & Laboratory Air Systems – 7.5 & 10 HP Pumps

Powerex

•

150 Production Drive

•

Harrison, OH 45030

•

USA

P 1.888.769.7979

•

F 513.367.3125

•

www.powerexinc.com

IN594402AV

•

06/2017

Page 24 of 28

Servicing the Scroll Pump & Motor

The Powerex Medical and Laboratory Air 7.5 and 10 HP systems are

equipped with a slide system for the baseplate assemblies to facilitate

pump and motor access for maintenance and if necessary, repair. To

utilize the slide, identify the base mount assembly needing attention

and lock out and tag out the power sources, both electrical and

pneumatic. (Utilize the lockable motor protector circuit breaker and

the isolation ball valves.) Verify that the compression side flex hose

from any nearby sets do not interfere with the slide assembly, make

any adjustments necessary and prepare to slide out the baseplate.

Loosen the nuts on the bolts that secure the L-bracket to the slide

rails. It is not necessary to remove the bolts, and the elastic stop nuts

are provided to facilitate keeping the bolts secure in the L-bracket

holes.

To Pull Out the Pump Side

Remove pressure from the discharge side of the pump by actuating

the safety valve upstream of the isolation valve in the outlet line.

Then remove the braided stainless flex hose from the set. Loosen

the bolts holding the L-brackets to the baseplate on the side you are

pulling so they can lift up over the head of the rail to frame securing

bolt. Now carefully slide the set outward. The back L-bracket will be

restrained at the midpoint by the end of the long slot. The pump will

now be accessible for service actions. When complete, reverse the

disassembly steps.

On multi-stack systems the motor side may be pulled outward

toward the tank dryer skid by a similar process. On single stack system

the air filter group may obstruct motor access on some tiers. In those

cases, pull the slide out the pump side, unbolt the pump and transfer

the L-brackets to the closer long slot, now pull out the motor until

access is achieved.

NOTE:

If pulling out for motor access the motor leads and conduit

may need to be detached to achieve sufficient travel.

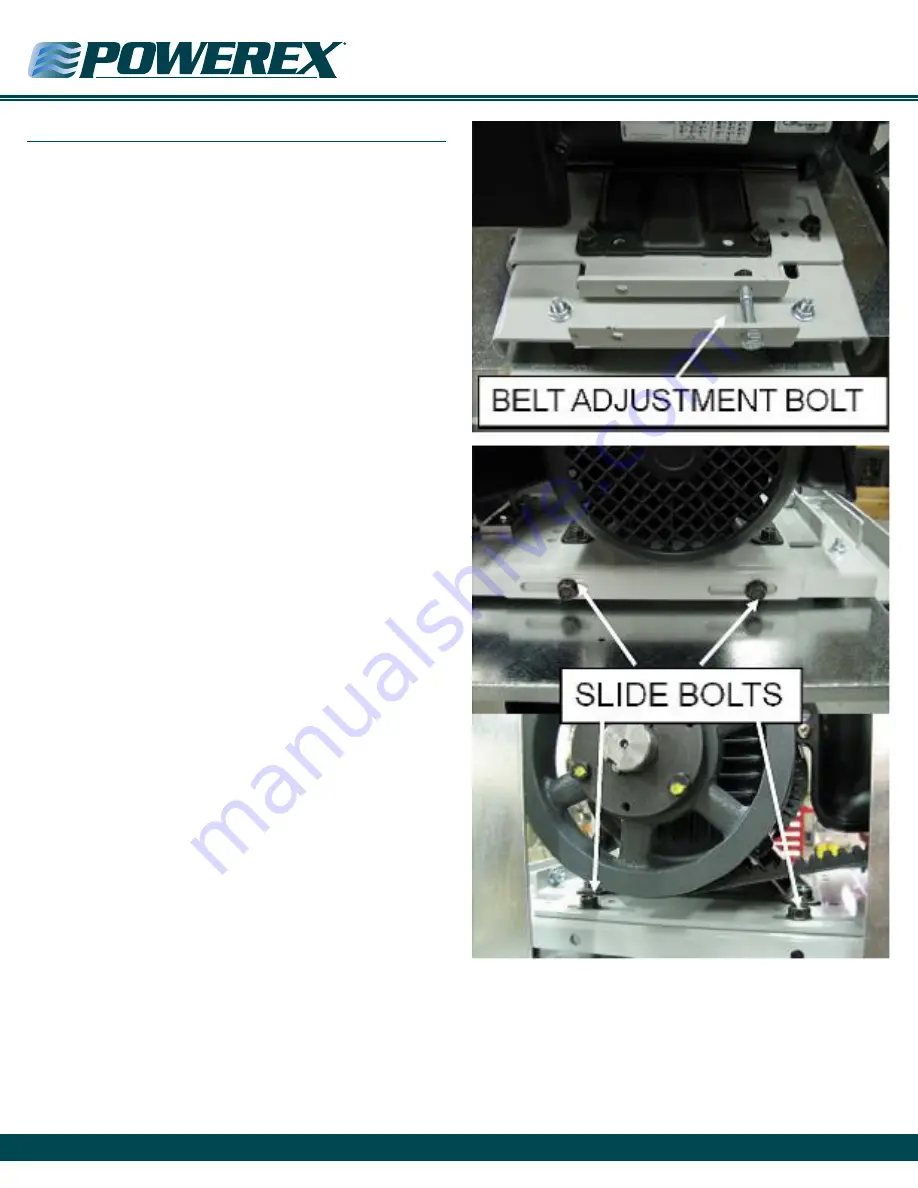

Using the Motor Slide Base to Tension the Belts

Belt tension is set at the factory. If slippage is detected, reset the

tensions as follows:

After the first 200 to 500 running hours or at any time chirping is

heard on startup, check the belt tension. If tension is below 25 pounds

on any belt, increase the center distance using the motor slide base

so that belt tension is 45 to 50 pounds. The motor slide base details

are shown below. If installing new belts see the procedure below.